GROUNDFORCE Shorco has been supplying a range of large-capacity modular hydraulic shoring equipment to contractors building the new Govan to Partick Bridge in Glasgow.

The firm has been helping main contractor Farrans with the construction of the piers at either end of the landmark crossing by supporting the large sheet-piled cofferdams in which the structures are being built.

Work started on site in January 2022 and Groundforce Shorco has already delivered the equipment to support the next cofferdam on the northern bank of the river.

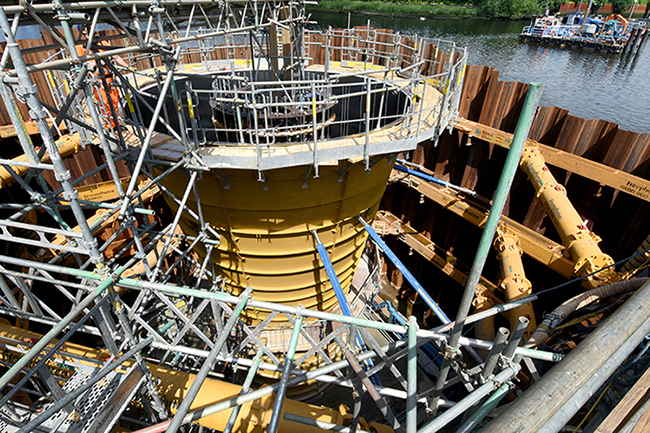

The cofferdam on the southern bank encloses the location for the new bridge’s swing mechanism. Measuring 15.5m x 15.5m, the sheet-piled cofferdam was supported by a combination of Groundforce Shorco’s Super Mega Brace and its modular hydraulic props.

The props employed comprise four each of Groundforce’s MP150, MP250 and MP375 (150, 250 and 375-tonnes capacity respectively) units assembled at four levels within the excavation. The props are around 7.2m long and the span between them is 5.5m.

Ahmed Adayem, Groundforce Shorco senior engineer, explained, “To deal with the heavy hydraulic loads acting on the structure, standard 508mm-diameter extension tubes were fitted to the MP150 props at the top of the cofferdam. The intermediate-level MP250 props are fitted with 610mm-diameter tubes and 813mm-diameter tubes are fitted to the MP375 props.”

The permanent works in the south cofferdam is complete and temporary support has been dismantled.

The focus more recently has shifted to the north bank where the second cofferdam is located ready for construction of the abutment and pier to support the moveable end of the swing bridge.

This cofferdam, like its counterpart on the south bank, also measures 15.5m x 15.5m and the Groundforce Shorco equipment will be installed in a similar configuration.

Design of the cofferdams and their supporting structure is said to have been complicated by the fact that this part of the River Clyde is tidal, with the water level rising and falling roughly four metres twice a day. Consequently, the depth of the excavation from the top of the sheet-piled wall to formation level is approximately 12m.

Fluctuations in the tidal loadings are managed by pre-loading the propping system using the integral hydraulic rams. Groundforce Shorco has supplied its wireless load-monitoring system to track loads in real-time and send alerts via SMS message should any load exceed the pre-set value. The system also allows the customer to keep an eye on loads and adjust the propping system accordingly.

Farrans site agent Luis Alves added, “We have a long-standing relationship with Groundforce Shorco having worked with them several times in the past four years. We’ve recently worked with them on a couple of big dockyard projects locally, so we know their capabilities.

“I have previously worked with (Groundforce Shorco major project manager) Adam Fletcher, and the engineering team at Groundforce Shorco are very helpful. We’ve had a couple of design changes to accommodate this job and they have been very supportive.”