Owen Batham, sales and marketing director at Elite Precast Concrete, explains why in an industry where safety, speed, and stability are non-negotiable, it is often the simplest innovations that make the greatest impact

For scaffolding contractors across the UK, one such innovation quietly transforming site operations is the widespread use of precast scaffold ballast blocks from Elite Precast Concrete.

At first glance, a concrete block might seem modest in ambition. But when you consider the daily complexities contractors face, such as, unpredictable ground conditions, changing weather, tight deadlines, and ever-stringent safety regulations, the value of a reliable, purpose-built ballast solution becomes clear and that’s precisely what Elite Precast scaffold blocks deliver.

Reliable stability in every condition

Traditional ballast methods, from makeshift timber supports to loose materials, often lack the predictability and durability required for modern scaffolding. Elite’s precast blocks, engineered from high-strength concrete, provide a consistent, heavy counterweight that dramatically improves base stability. This is especially important when scaffolding is combined with sheeting, fencing or hoarding exposed to the Scottish high winds.

By offering even weight distribution and predictable load-bearing capability, these blocks reduce the risk of movement, settlement, or tipping. All common hazards that can compromise both productivity and safety on site.

Enhancing health and safety on the ground

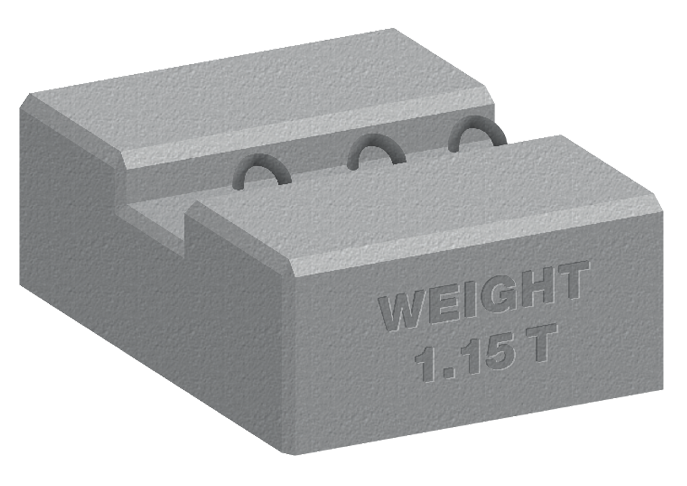

Safety isn’t just about avoiding collapse; it’s about reducing exposure to everyday risks. Precast scaffold blocks help here too. Their uniform design, complete with lifting points, enables mechanical handling rather than brute force manual lifts. A significant benefit given manual handling injuries in construction.

Moreover, the use of factory-produced blocks eliminates the need for on-site casting or ad-hoc ballast solutions, reducing dust, noise, and manual processes that contribute to long-term health concerns.

Efficiency meets practicality

We understand that time is a contractor’s most valuable commodity, and anything that simplifies setup and teardown delivers real bottom-line value. Precast blocks arrive ready to deploy, eliminating the time-consuming preparatory work associated with site-built bases. Their consistent shape and weight mean scaffold teams can plan more effectively, reducing delays and improving overall workflow.

This efficiency extends beyond installation; the blocks are 100 % recyclable, reusable and can often be redeployed between projects, supporting both sustainability goals and cost-effective asset management.

A proactive solution for modern challenges

In the current landscape of construction work where regulatory compliance, workforce welfare and environmental responsibility are all high priorities, our scaffold blocks offer a practical, forward-looking tool that aligns with industry needs. Whether stabilising complex scaffolds, securing hoardings, or supporting temporary works, these blocks help contractors deliver safer, smarter projects.

The humble concrete block may not make headlines, but for scaffolders and site managers alike, its contribution to safer sites and smoother operations is anything but plain.