By Stewart Smart, estimating manager at Roger Bullivant Limited

SCOTLAND’S industrial and infrastructure landscape is evolving, and with it comes a growing need for foundation solutions that are not only technically robust but also environmentally responsible. At Roger Bullivant Limited (RBL), we’re proud to be at the forefront of this shift, offering Continuous Helical Displacement (CHD) piles, a smarter, sustainable alternative to traditional CFA piling.

CHD piles are cast insitu using a specialised multi-flight auger that displaces soil laterally as it drills, rather than removing it. This technique produces minimal spoil, making it particularly well-suited to contaminated sites and urban environments where waste management and disruption are key concerns.

Once the required depth is reached, up to 27 metres depending on ground conditions, concrete is pumped under pressure through the hollow shaft and out of the tip as the auger is withdrawn. Reinforcement is then placed into the bore, completing a pile that offers excellent load-bearing capacity and reduced settlement.

This method not only improves soil strength through compaction but also shortens pile designs and reduces concrete volumes, resulting in lower embodied carbon and faster installation. It’s a technique that blends the performance benefits of both displacement and non-displacement piles, with minimal vibration and a cleaner site footprint.

Delivering results across Scotland

Through early engagement with Morgan Sindall Construction on the Orbiston Community Hub project, RBL developed a more sustainable piling scheme through the conversion of 344 No x 16m deep 600mm diameter CFA piles to a combination of 300/600mm and 400/700mm diameter CHD piles to a depth of 8m. This showcases the benefit of enhanced load capacity through the unique design of CHD piles resulting in 50% reduction in pile length on this project, which in turn resulted in significant environmental benefits.

Through discussions with Heidelberg Materials UK up to 70% of Portland Cement in the original concrete mix was replaced with Ground Granulated Blast Furnace Slag (GGBS).

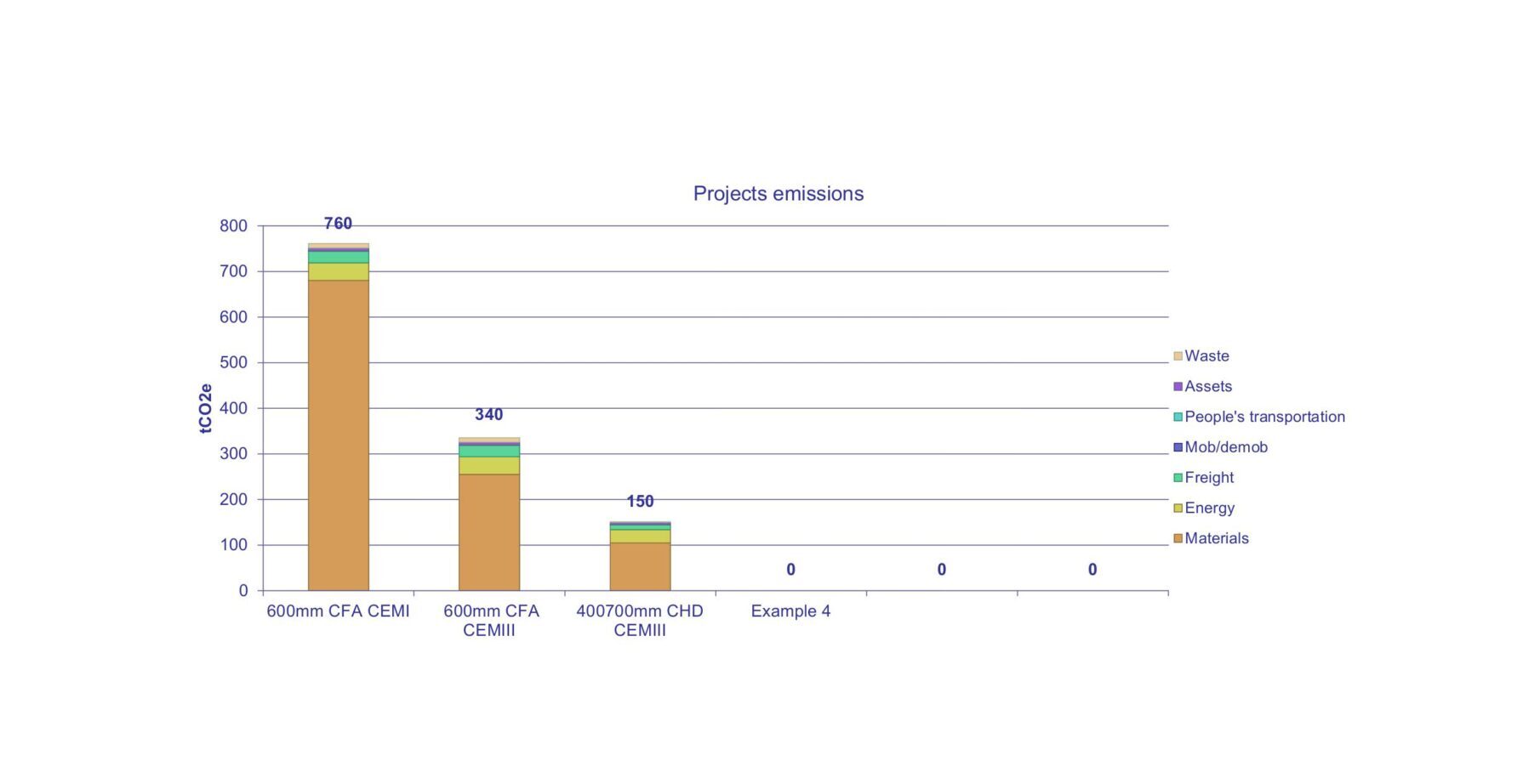

The graph below shows how in comparison to the original 600mm diameter CFA scheme using a CEMI mix, we saved 610 tC02e through the design and implementation of the RBL’s CHD system.

A better alternative to CFA

Compared to CFA piles, CHD piles offer a range of advantages that make them ideal for all sectors:

• Minimal spoil to remove, reducing environmental impact and transport costs

• Enhanced load transfer and improved soil strength

• Negligible vibration, ideal for sensitive or urban sites

• Shorter pile designs and reduced concrete usage

• Fully automated, monitored installation for quality assurance

Whether you’re planning a logistics hub, industrial unit, or infrastructure project, CHD piles offer a foundation solution that’s cleaner, quicker, and more sustainable. With a proven track record across Scotland, RBL is ready to support your next build with smarter ground engineering.