A new ‘tentacle-like’ underwater robot that can safely interact with offshore structures could help revolutionise how millions of kilometres of subsea infrastructure is inspected and maintained, developers have said.

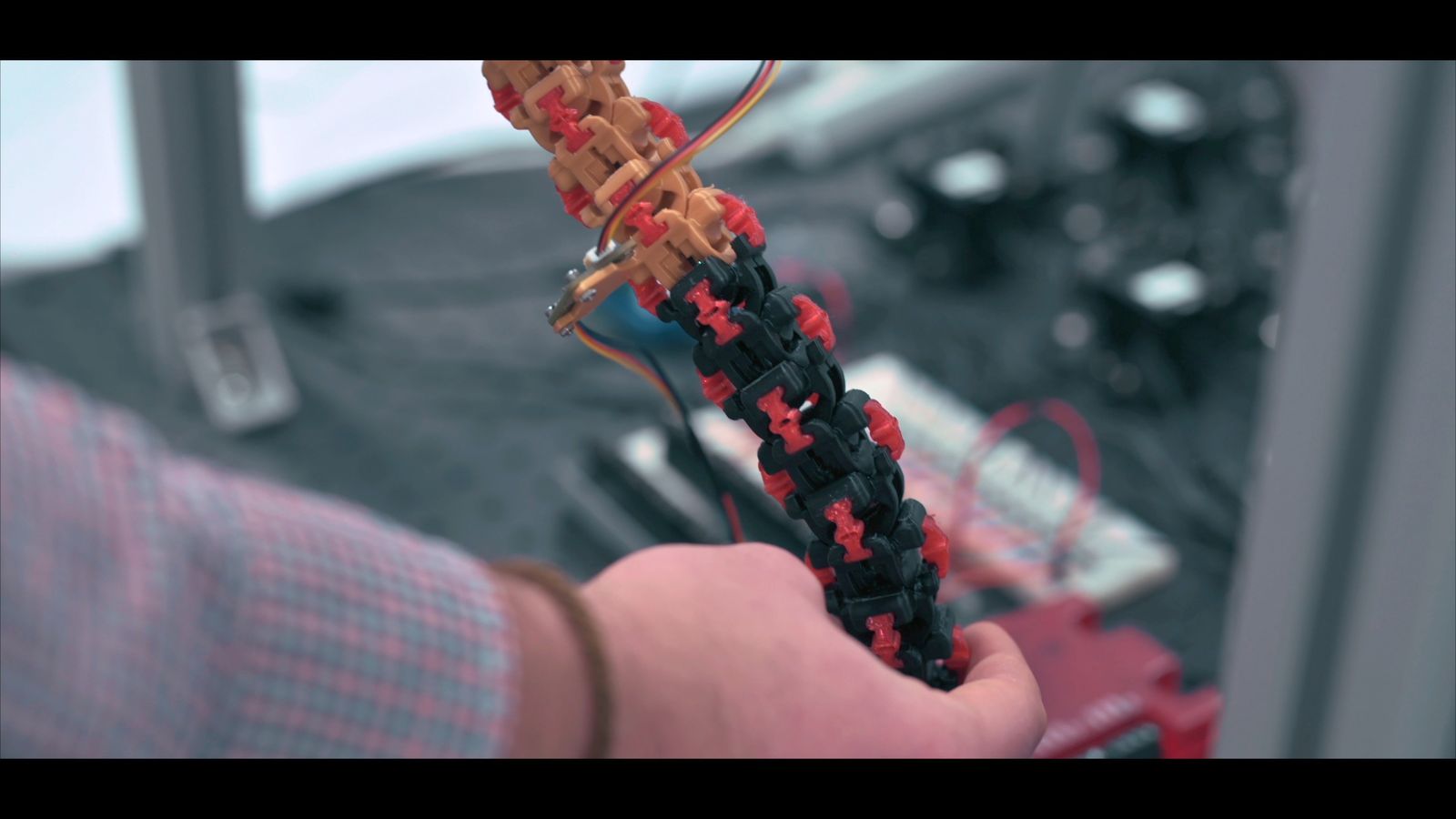

Created through a collaboration between the UK’s National Robotarium in Edinburgh and Senai Cimatec in Brazil, the one-metre-long flexible manipulator features a soft, bendy design that conforms to structures during contact. Developers said this offers ‘significant advantages’ over conventional rigid manipulators when working near delicate or complex subsea equipment.

The breakthrough addresses key challenges in offshore inspection, where subsea pipelines and equipment at depths reaching nearly 3000m must be regularly checked to ensure safety and prevent costly failures. With offshore infrastructure decommissioning costs estimated at over $100 billion by 2030, extending the safe operational life of existing pipelines and equipment delivers both significant economic savings and reduces environmental impact.

The robot, which has been designed and developed by engineers at the National Robotarium, the UK’s centre for robotics and AI at Heriot-Watt University, works by combining a flexible backbone with a system of tendon-like cables that control its movement. Special sensors help it understand its position and shape underwater, allowing the robot to make precise movements even in turbulent conditions. This makes it ideal for deploying from underwater vehicles to inspect offshore wind farms, as well as other offshore energy and marine infrastructure.

Tests conducted at the National Robotarium’s wave tank facility show the robot can position its tentacle-like arm with remarkable accuracy and maintain stability when subjected to external forces of up to 300g. Even when intentionally disturbed, it can correct its position and return to the desired state within seconds – a crucial capability for operation in unpredictable ocean environments.

Rowanne Miller, project manager at the National Robotarium, said, “This breakthrough represents a significant milestone for the National Robotarium, showcasing our comprehensive end-to-end project delivery capabilities. Our team has taken this innovative underwater robot from initial concept through design and development to successful testing in real-world conditions. What makes this particularly exciting is that we’ve created a solution that doesn’t just incrementally improve existing technology – it fundamentally changes how we can approach underwater inspection tasks, opening up new possibilities for safer, more precise interaction with critical subsea infrastructure and potentially transforming how we maintain and protect our offshore assets for decades to come.”

Lucas Silva, lead researcher at SENAI CIMATEC, added, “We worked together with the National Robotarium to conceive an innovative take on underwater manipulation, opening up new use cases for the industry. This new branch of development represents an important and disruptive upgrade to our robotics development roadmap, and the seamless cooperation with The National Robotarium played a key role in this new achievement, setting new standards for future international partnerships”.

The technology is primarily aimed at offshore energy companies, underwater inspection service providers, and operators of subsea infrastructure who conduct regular safety assessments. Traditional inspection methods often require large vessels and human divers, creating both safety hazards and significant carbon footprints. It is hoped the innovation could enable smaller underwater vehicles to perform sophisticated inspection tasks, substantially reducing operational costs while improving personnel safety and environmental sustainability.