Arthur Postl, head of sales Doka Slipform, explains why the evolution in Slipform construction over the past three decades shows exactly how smart technologies can refine a solution that is integral to the construction process

The use of a floor-level ‘bullseye’ laser point and a rig-affixed laser target is firmly established as a method of measuring a structure’s verticality throughout the slipforming process. But the activity is not without its flaws. Poor weather or heavy rain can diminish the laser’s visibility on the traditional target and may lead to a rig ‘climbing blind’. This could jeopardise the core’s verticality and may risk the misalignment of door openings and other apertures, which might prevent a structure from being built as designed.

The more traditional plumbline method, using a vertically suspended weight, is also still prevalent during Slipform construction. Again, this offers significant challenges in ensuring a structure’s verticality. For rig operatives, the plumbline method, whether laser-accompanied or not, often requires regular manual positional adjustments. This could routinely involve visits to a suspended deck to check alignment, or journeying many metres via hoists or stairs to assess the floor-level lasers positioned below.

Drive for precision

Reducing the need for manual visual interventions to ensure high-rise cores are built with precision and verticality can ensure Slipform programmes make smarter progress. Doka responded with a sensor-based system that delivers real-time measurements of plumbing, alignment, and height. This reduces the need for manual checks and improves accuracy.

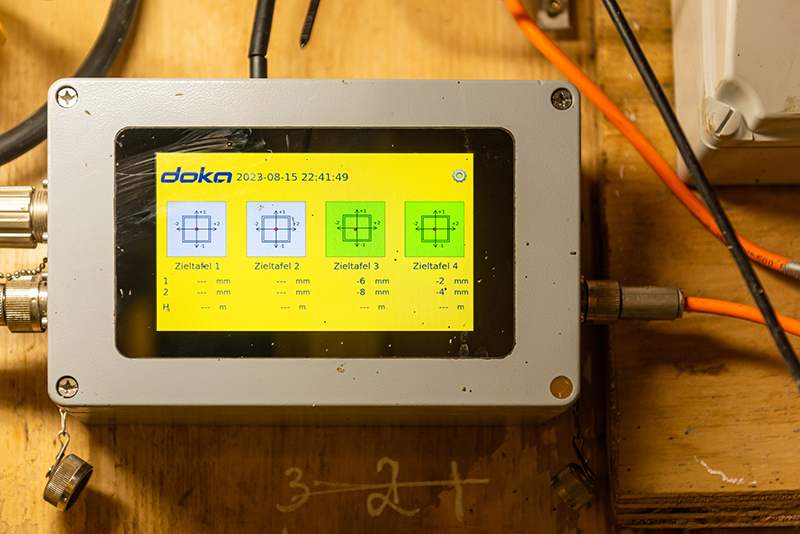

The digitised process, called DokaXact Slipform, is part of the DokaXact family of sensors and can help bring greater certainty to the construction of a building’s core elements. Its function involves multiple lasers and sensors sited on the Slipform rig. These communicate with a wireless processing unit to visually display the information to the site teams for their programming and defined survey point data. The assessed data is available for download via an app, allowing Slipform operators to also remotely monitor and record the rig’s position quickly and safely.

The as-built dimensions of the preceding sections can provide a blueprint for the positioning of additional structural elements and follow-on trades. The app provides site operatives with guidance during the positioning process, ensuring the system is plumbed and aligned with greater accuracy.

For the contractor, clients and other stakeholders, downloadable live data on a rig’s height positioning above the ground is also available. Supporting the site teams with the placement of embedded elements and box-out sections, the Cloud-based capability offers the assurance of a project’s progress, remotely.

Sensor systems with this capability can achieve accuracy down to ±2mm, enabling an element to be built more easily within the predefined structure tolerances. This reduces time-consuming finishing work and resulting expenses for subsequent trades including, for example, lift installers.

The autonomous benefits of the sensor system’s intuitive function can greatly benefit the site surveyor in their role. Using the system could help accelerate progress and potentially reduce downtime on the project by enabling other resources.

Validation

Trials are separately progressing to validate the use of a digital concrete maturing measurement system as part of a Slipform building programme. If successful, it will give operatives greater control over the core construction process and make smarter work of producing concrete that is intrinsic to a project’s precise requirements.

The trials involve Doka’s Concremote system, which features sensors that accurately measure temperature and calculate a concrete structure’s compressive strength in continuous real-time. This can improve understanding of the concrete’s performance, paving the way for a high-quality finish that further optimises processes on site.

With companies demanding more sustainable concretes, concise curing data allows users to select solutions based on cost efficiencies and environmental performance. This real-time capability also allows quick, informed decisions on critical paths. Data produced in this way can be stored and used time and again to speed up specification and help improve future project planning.

Next-generation digital tools are reshaping Slipform construction. By improving control, consistency and quality, they help contractors manage time, cost and sustainability more effectively.