Concrete is a crucial material in construction, essential for infrastructure, housing, and even renewable energy projects. Yet, its climate impact cannot be ignored. In this article, scaffolding and formwork specialist Doka says the challenge is clear: how can we make concrete more climate-friendly?

Future demands on concrete formwork

Scotland has committed to reaching net-zero emissions by 2045, five years ahead of the UK target. This is accelerating efforts to decarbonise the construction industry, where cement and concrete are major contributors to embodied carbon. Frameworks such as the Net Zero Public Sector Buildings Standard and the Scottish Climate Change Plan prioritise the use of low-carbon materials. However, practical challenges remain – especially for the use of low-carbon concrete in cold conditions.

New concrete mixes, new challenges

There are three primary approaches to reducing CO2 emissions in concrete production. The first focuses on optimising the cement production process by using alternative fuels and improving energy efficiency. While this has led to significant reductions, further progress is slowing. Emerging tech, such as CO2 capture and storage, show promise but remain costly and face some technical hurdles.

The second approach involves advances in concrete technology. High-performance mixes with dense structures reduce material demand but are expensive and complex to produce. A more common solution is reducing clinker content in concrete mixes, a practice initially driven by cost savings. Further reductions face regulatory constraints, though some countries are exploring lower minimum binder content when performance can be verified.

The third approach is developing novel binders that reduce or eliminate cement clinker by using supplementary cementitious materials. One example is using Portland-limestone cement (PLC) in place of traditional Portland cement. PLC contains a higher percentage of limestone (typically 5-15%), which reduces the need for clinker, the most carbon-intensive component of cement. Additionally, there are alternative materials like geopolymers or calcined clays which are meant to replace traditional cement or at least a certain amount of cement. While technically possible, these alternatives are currently limited to niche applications.

Charting a new, more sustainable path forward

The cements in use today can´t be easily replaced by new clinker-reduced cements, because the components do not act in the same way. The required concrete compression strength cannot be reached as easily, especially with certain temperature conditions. Concrete compositions will need adjustment to ensure each project’s technical requirements are met and they can perform as expected in practical applications under real-world conditions. Contractors and ready-mix concrete suppliers should be aware using cement with lower clinker content may slow the concrete’s reaction time. This can delay the setting and hardening of the concrete, and the compressive and tensile strength of the concrete develops more slowly.

In some cases, this slower process can cause the opening of element joints of the formwork. This happens when fresh concrete pressure is increased due to different assumed setting behaviours and the height and speed of concreting are not adjusted accordingly. In addition, if the system is overloaded, the connecting parts may fail or collapse.

Cold or even cool ambient temperatures can cause delayed development of the early age compressive strength in these new concrete mixes, especially between autumn and spring months. When the strength development slows down and more time is needed to reach the required concrete compressive strength, it can cause major challenges and delays. Previous wisdom such as ‘pour in the afternoon and remove the formwork the next morning’ can no longer be assumed to apply.

On the other hand, we also know in some cases slower curing times can increase the concrete quality and reduce the risk of cracks. However, concrete contractors are frequently under pressure from tight project timelines, so the requirements of quality and efficiency must be balanced.

New formwork technologies enable sustainability

New digital solutions and initiatives can accelerate the green turnaround on construction sites. Above all, they help to ensure that CO2-reduced concrete mixes can be used safely and productively on jobsites globally.

Products like Doka’s Concremote and other sensor-based solutions like DokaXact Pressure provide data on temperature and strength development in real-time, which enables improved control of formwork and in-situ concrete work. Everything from stripping times and curing times to the earliest time for prestressing can be derived from these concrete pressure measurements.

Another exciting development is Intelligent Heated Formwork, which enables the efficient and safe use of CO2-reduced concrete mixes, even in low temperatures. Since these innovative concretes take longer to cure, the heated formwork provides a targeted ‘heat boost’ to accelerate early strength development and reduce curing times. Doka’s intelligent heated formwork prototype has already proven its effectiveness in an Austrian research project ‘Reduced Carbon Concrete – RCC2’. The results showed that in cold weather conditions, heated formwork was essential to ensure proper strength development, prevent structural damage, and enable CO2-reduced concrete to be used reliably on-site. Without this support, freezing temperatures can significantly impact the material’s performance and safety.

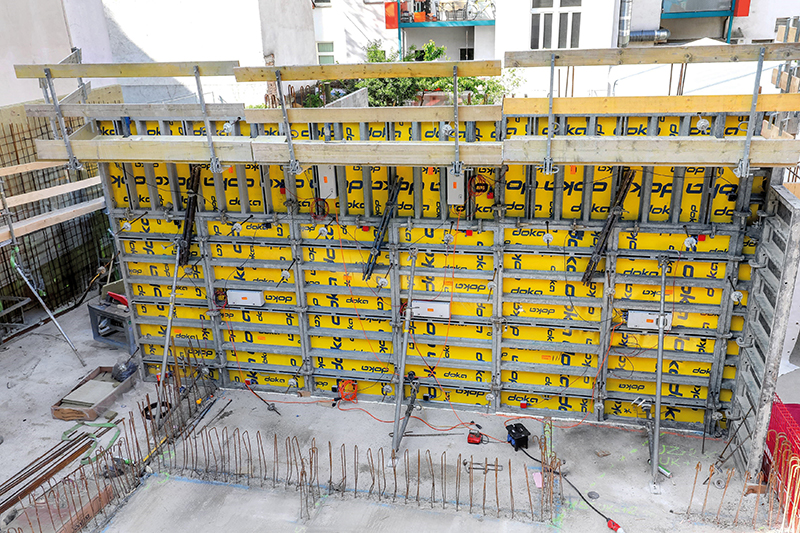

Field-tested in Vienna

One of the first real-world applications of Intelligent Heated Formwork (IHF) took place at the SOLEY housing development in Vienna. Developed by STRABAG Real Estate, the project combined RCC2-certified low-carbon concrete with IHF for wall construction. Doka’s Concremote sensors were used to monitor concrete compression strength in real time. The pilot confirmed the feasibility of accelerating curing while maintaining efficiency and quality.

Embracing low-carbon concrete in extreme winter conditions

In Norway, a significant stride has been made toward sustainable construction at Cissi Klein Upper Secondary School in Trondheim, where the construction team proved they could use innovative techniques to reduce carbon impacts, even in harsh winter climates. The project exclusively utilised CEM III low-carbon extreme concrete paired with heated formwork, reducing CO2 emissions by over 50% compared to traditional concrete. This stands as the world’s first school building fully cast with this innovative concrete type, challenging the assumption low-carbon concrete cannot withstand sub-zero temperatures.

As the industry moves toward more sustainable practices, embracing low-carbon concrete and advanced technology will be essential to achieving net-zero targets. The challenges of slower strength development, temperature sensitivity, and project timelines can be effectively managed with smart formwork solutions, real-time monitoring, and innovative heating technologies. By continuing to innovate and adopt climate-conscious construction methods, we can build the future with resilient, efficient, and low-carbon concrete solutions.

Doka is preparing to bring the IHF system to market in 2027, with initial rollout planned for Scandinavia – a region where long cold seasons make curing support essential. Given Scotland’s similar climate challenges and accelerated net-zero timeline, early adoption of these technologies could provide a competitive advantage in meeting sustainability requirements while maintaining construction efficiency.