AN innovative bunker excavation project in Glasgow has been helping to pave the way for the South Clyde Energy Centre, a transformative energy-from-waste (EfW) facility which is scheduled to be operational by the end of next year.

The centre, which is jointly owned by Fortum and Gren Energy, will generate energy for the city from non-hazardous domestic and commercial waste left over from the recycling process. The site is tipped to help divert up to 350,000 tonnes of waste away from landfill each year and generate enough electricity to power the equivalent of up to 70,000 homes.

Earlier this year, Project Scotland reported that Doka supplied more than 150 tonnes of Slipform equipment to aid the construction of concrete walls at the project. Doka designed the system for the energy centre’s 22-metre-high waste unit.

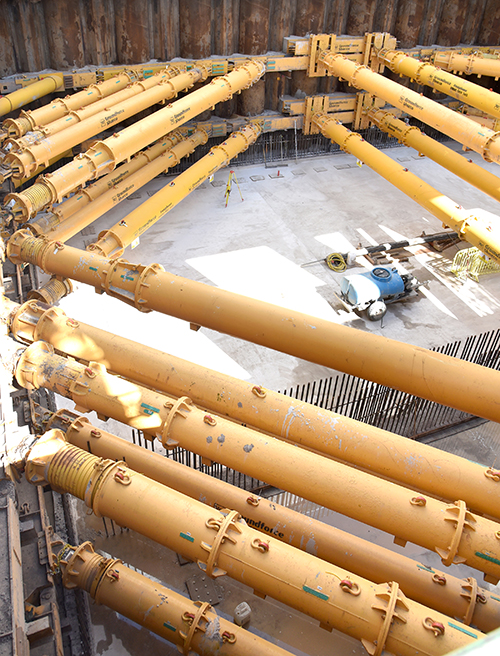

The bunker excavation dimensions are a whopping 34m x 25m. For this element of the scheme, equipment specialist Groundforce Shorco worked with contractor Careys to provide two levels of temporary propping to assist with the dig. The project has utilised some of Groundforce Shorco’s heaviest capacity kit, including the Super Mega Brace, fixed tubular steel sections, MP375 props, and 813mm diameter tube.

Groundforce Shorco’s temporary propping solutions were in operation for six months, with deliveries meticulously planned to arrive on site at set times from the firm’s major projects depot in Derby. At certain points, two or three deliveries of props were arriving per day, with some of them being transported in sections.

The bunker excavation proved particularly complex due to the nature of the wet material in the ground, amusingly described as ‘slop’ by Adam Fletcher, commercial manager, major projects, at Groundforce Shorco!

“It is a tricky design,” Adam told Project Scotland. “The bunker is rectangular in nature. The unusually shaped sites are usually the hardest ones, but this was particularly challenging due to the nature of the ground and very, very high loads.

“We’ve used our Super Mega Brace, which is the heaviest proprietary beam on the market currently. Even that was a challenge as the centre wasn’t strong enough to take the loads. We had to double the beam up in the middle to take out combined forces from the knee-braces. We’ve got a series of knee-braces all around the excavation, which would push the forces centrally and concentrate them on the beam in the middle.

“We also used our MP375 props. Pretty much every prop on the job is load monitored.

“We used 813mm-diamater tube as opposed to 1220mm-diamater, because the prop lengths are quite manageable. The 813 gives a decent carrying capacity. That’s helped with clearances, muck away, and keeping things as lean as possible.

“The loads were so high in the extreme corners that we couldn’t get our props to work under the hydraulic pressure, so we built some structural steel props with a thicker wall on the tube to take that force.”

Robert Powell, principal engineer at Groundforce Shorco said the twinning aspect is one of the key learnings the business will take from this project and use on future schemes.

“As Adam said, we twinned the waling beam in the centre where all the loads were concentrated,” he explained. “That initially was a design issue we had to overcome. What we’ve done before is twin the whole frame, so you end up with a double level frame to share the load. But having spoken to some of my colleagues who have done similar things in Europe, they suggested just doing this locally, which almost halved the amount of waling beam needed and reduced the number of struts. That’s certainly something we can take forward.”

Project Scotland visited the site towards the end of Groundforce Shorco’s involvement. The team emphasised that an abundance of value engineering and tweaking fine movements of props has helped ensure successful delivery.

One of the key elements was early engagement. Pat Grenham, senior project manager at Careys, revealed the business approached Groundforce Shorco over a year before the excavation got underway. Groundforce Shorco and Careys’ respective design teams worked closely to come up with a bespoke solution that ticked all the boxes.

Robert added that collaboration resulted in a change to the original concept.

“Because of the ground conditions, the design evolved from a standard concrete piled wall to what we eventually ended up with, which is a combi wall… and that’s had a knock-on effect on the loads that have been supplied. You need that early engagement so that you’ve got the time to develop the solution.”

Regarding collaboration, Pat referred to the load monitoring system, which was analysed daily to check what loads were going into the props, to make sure it was still within the tolerance.

“The props haven’t been over-strained, so obviously the design is working,” he stated. “Along with load monitoring, we also survey whether there’s any deflection or movement in the props.”

Two 13-tonne excavators and a crawler crane are among the heavier items of plant that have been involved in removing the material.

Given that the facility will ultimately play a key role in creating Scottish energy resilience and supporting the nation’s environmental goals, sustainability has naturally been a major consideration during the construction process.

Both Groundforce Shorco and Careys have made huge strides in attempting to reduce their carbon footprints in recent years, adding to the synergies between the firms on this project.

Pat explained, “At Careys we use FSC-timber and GBBS (ground granulated blast furnace slag), which is a cement replacement. All our new excavators have the latest technology to reduce emissions. All our plant is low emission, including our fleet of vans. We are working towards trying to be as sustainable as possible.

“We also use recycled material. The material that is excavated is mostly reused on site or taken away by others to be used again. Nine times out of ten, our tools are electric.”

From Groundforce Shorco’s perspective, Adam revealed that hydraulic propping boosts sustainability goals by virtue of the fact they are reused repeatedly.

“A lot of these products have at least a 10-year lifecycle,” he added. “They’re used, re-used, and maintained. Traditionally, you would have used a structural steel solution. That steel would have been bought in, you’ve got the embodied carbon from the start, you’ve got the cutting, the welding, and the wastage/scrappage at the end of the job.

“By its very nature, what we do is a good thing because you are reusing it. We’ve now got a QR code on every one of our designs, so every single job that we send out has a code you can scan that shows the embodied CO2 per hire of the kit, per week. You can compare it against steel. It’s probably a 50% saving on carbon versus structural steel.”

Robert added that environmental considerations are taking increasing prominence when designing projects of this magnitude. Groundforce Shorco has studied the embodied carbon of its equipment, including what share of embodied carbon each project should take out of its lifecycle.

“We came up with a formula and can specify on our designs what the embodied carbon is per week, so however long the equipment is hired for the contractor can use that to feed into their project calculations and compare against other options,” Robert explained. “Generally, proprietary shoring, with it being reusable, is a sustainable way of propping these types of excavations.

“We’ve got depots all over the country, so we try to specify equipment from local depots. This project, because of its nature, needs some specialist equipment which is only stocked in our dedicated Derby Depot.”

The EfW build has supported hundreds of construction jobs in Scotland, while the use of local businesses has added to the scheme’s green credentials. Local companies have supplied the tools, Thornbridge Timber – which is based almost literally next door to the site – provided the timber, while the rebar came from Motherwell.

Adam concluded by stating that the project has provided a major showcase for Groundforce Shorco’s equipment solutions. He revealed that in the 16 years he has been with the business, the designs have become progressively more complicated, necessitating the need for ever more innovative thinking.

“I started out using 2D CAD and now we’re using Revit 3D modelling,” he said. “You work very closely together and end up almost like a design team yourselves. You do find efficiencies. You find problems and all sort of solutions as well. It’s a learning curve. You learn something new on every single job and take it forward to the next one.

“Careys and Groundforce Shorco will be richer for the knowledge overall (gained on this project).”

Pat agreed, hailing the teamwork as being one of the key reasons why the project has gone so smoothly and to the required timescales.

“I’ve worked with Groundforce Shorco on numerous projects,” he said. “The pictures will paint a thousand words. Once you look at them you can see the achievement. We’ll give the end user a product that everyone should be proud of.”