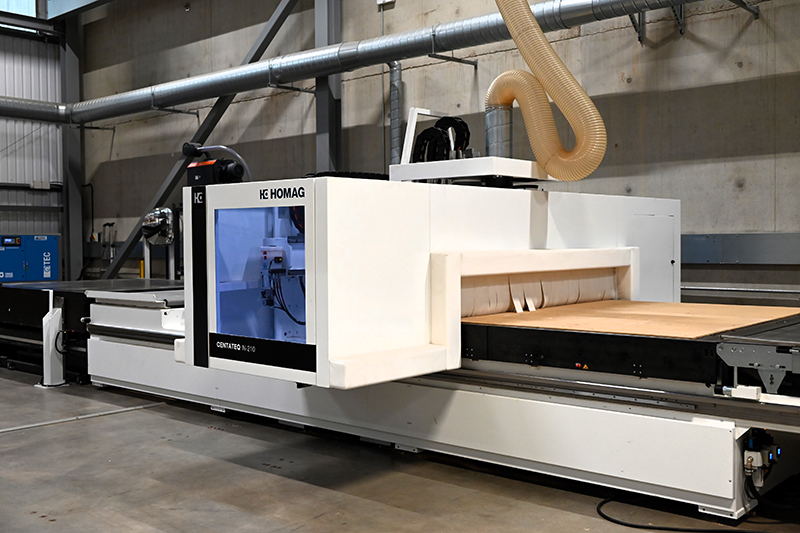

PERI UK has announced an investment of £250,000 to bring CNC machine cutting capabilities in-house.

The move is designed to reduce lead times for customers, particularly for replacement plywood panels used in formwork. Previously, these panels were cut to size in Germany before being shipped and assembled at PERI’s UK depots.

PERI added that the new machinery will also enable the business to offer more competitive prices without compromising on material quality, such as the Birch plywood used across its slab and wall formwork solutions.

The temporary works specialist revealed it is already experiencing ‘high demand’ for this service, having recently fulfilled a large replacement plywood order for PERI equipment currently in use at Hinkley Point C.

The CNC machine also future-proofs the company’s fabrication service, which produces over 100 sqm of bespoke temporary works elements on average each month. The machine will enable most aspects of the fabrication process to be brought in-house, which includes the ability to cut complex parts for intricate solutions, such as cleat boxes, to meet bespoke or freeform requirements.

Paul Cousins, panel & timber products manager at PERI UK, said, “We’re really pleased to be able to offer a replacement plywood panel service to our customers and provide additional support to our fabrication department when needed. We’re already seeing improvements in the speed at which we can replace plywood formlining and return our customers’ equipment to them.”

PERI said the investment has also created an opportunity to up-skill employees in CNC programming and operation.

In addition to the CNC machine, a new panel wall saw is being installed and will be in operation from January.