ADVERTORIAL

FORTH Valley Fabrications’ (FVF) continued investment in its operations is set to result in a busy final quarter of 2024 after the business secured full project packages alongside its continued flow of sub-contracting work.

Launched in 2010 by MD Michael Holmes, FVF began with just one other member of staff and a solitary van.

Today, it boasts a turnover of £10 million, has an extensive in-house plant fleet, employs over 80 people, and is based at a large fabricating site in Stirling which produces 5,000 tonnes of steel each year.

Specialising in design, structural steelwork, heavy fabrication, modular building, site erection, site services, metal works, and secondary packages, the company now offers full packages of work – with projects spanning all sectors of construction, oil and gas, nuclear, and railway.

Recent standout projects include the erection of steel at BAE’s new 170x80m shipbuilding hall in Govan, complex bridge restorations on behalf of Historic Scotland, and repairs to the seabed and foundations of an offshore Siemens’ facility in Fife.

Ongoing work includes steelwork at the build of HMP Highland, refurbish- ment at the University of Glasgow, as well as projects in Darlington, Norwich, Hull and Derby.

“We had very humble beginnings and that’s how the company has been built up on hard work and as an organic company,” Michael explained, before revealing the long-term growth plan which has seen the business built on the back of a continuous flow of increasingly large projects.

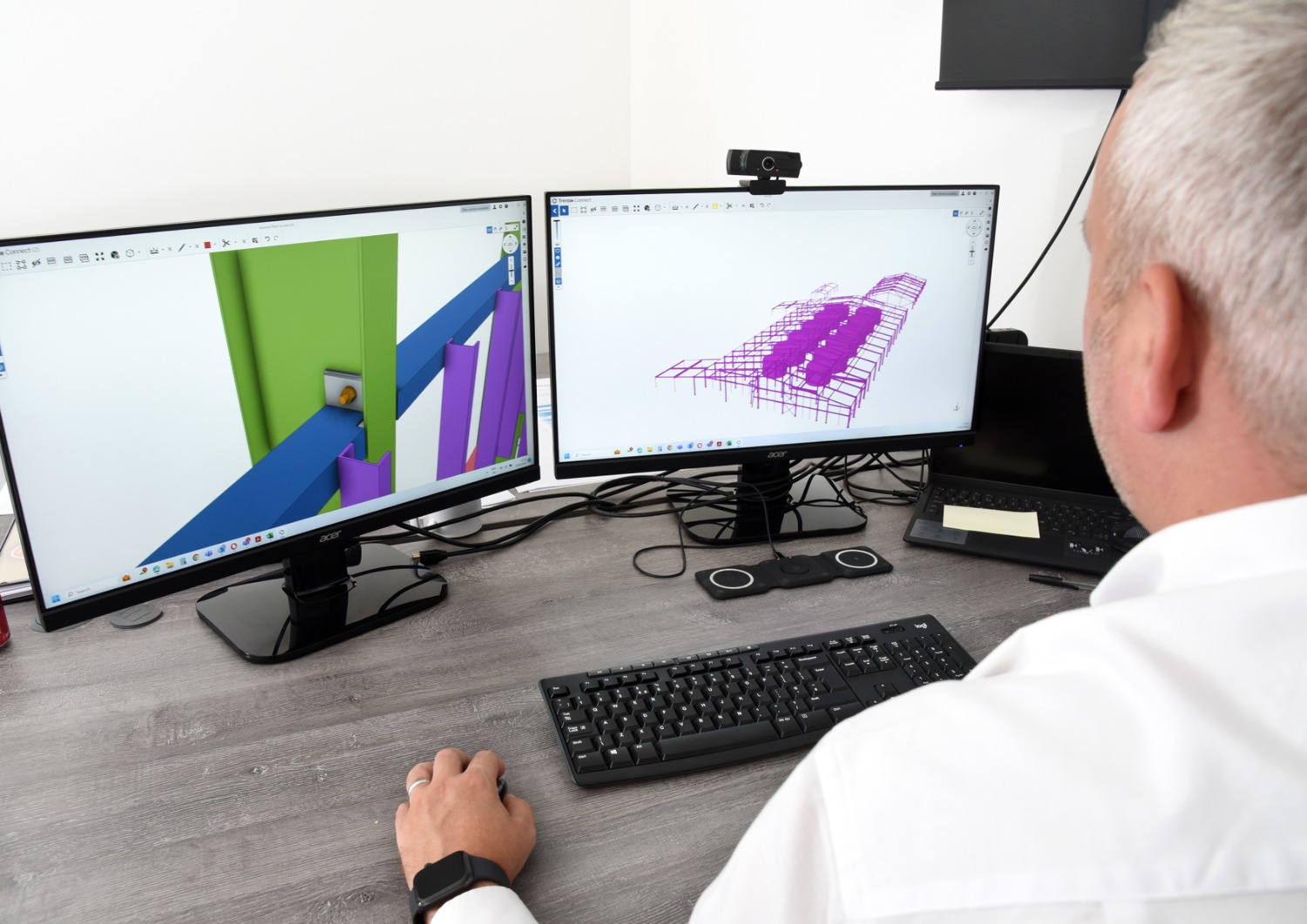

This year the firm has invested in Trimble software to aid in procurement and control of its fabrication facility. An in-house drawing office complete with a manager and team has also been added, while the production and estimation team has trebled in size. On the plant side, the purchase of a 70ft Liebherr crane has extended the mobile crane count to five, while new Merlo telehandlers have brought added flexibility.

These investments have enabled FVF to carry out projects in full – from drawing and design through to manufacture and delivery – offering an enhanced service to both new and existing clients across the UK. This has been supplemented with the appointment of John Brown as operations director and Steve Davis as construction director, two experienced steel professionals who Michael had worked with on past projects.

“I have known the potential within FVF and what it will become,” said John, who was previously a director at one of Europe’s largest steel businesses.

FVF recently secured a £2.6 million contract from a seafood specialist for the creation of a bespoke facility. The move to offer clients a full package of work is aimed at streamlining and speeding up projects at a time when delays are rife and the spread of work across various contractors can bring increased costs.

FVF’s integrated design and BIM systems enables real-time collaboration with clients, project management teams, and its procurement team throughout the manufacturing process to provide clients the opportunity to make live changes and receive immediate project updates.

“Having our own in-house drawing office just gives us that ability to service the clients there and then,” John added. “It gives us the ability to react and become more of a proactive business that can react to something when asked.

“Everything is done with structural 3D modelling and that allows us to get approvals and procurements quicker.”

With FVF producing 5,000 tonnes of steel per annum, and its erections teams handling around 750 tonnes of steel each week, a large talent pool is required. Key to this is the company’s dedicated training programme.

“We find that growing your own erectors, fabricators, and welders is the best way to do it,” John added. “We want projects delivered and the business promoted in a certain way – and the best way to do that is start from the ground and by training people.”

A number of apprentices are currently learning their craft both in the factory and on-site, as well as through FVF’s partnership with Forth Valley College’s Falkirk campus. Several senior team members began their journey as apprentices.

Looking towards 2025, FVF anticipates further growth and a busy year delivering full-package projects as well as sub-contracting work on behalf of long-term and new clients.

The flexibility and environmental benefits of steel are anticipated to see it continue to be the material of choice for a range of projects.

The design, cost, precision, and reliability is how John describes the benefits of working with steel. “There’s a whole series of design changes that can come quite quickly,” he added. “I think steel has a very diverse way of working in the industry.”