DOKA has told Project Scotland that its acquisition of scaffolding manufacturer AT-PAC will usher in ‘new standards’ for construction as Ringlock scaffolding system integration begins at Doka in the UK.

The collaboration between Doka and US-headquartered AT-PAC is already being realised and the Ringlock scaffolding system, certified by NASC and the Deutsches Institut für Bautechnik (DIBt), will become available through Doka’s UK operations towards the end of this year.

With access to Doka’s existing formwork systems and the incorporation of AT-PAC’s offerings, customers can now leverage ‘high-performance’ site scaffold solutions for various applications, including rebar and formwork access, working scaffolds, and stair towers. Doka added that this marks an ‘exciting new chapter’ for the company’s clients and construction contractors in the UK, who will benefit from enhanced support alongside the availability of AT-PAC’s UK stock and branch locations catering to scaffold contracting and industrial markets.

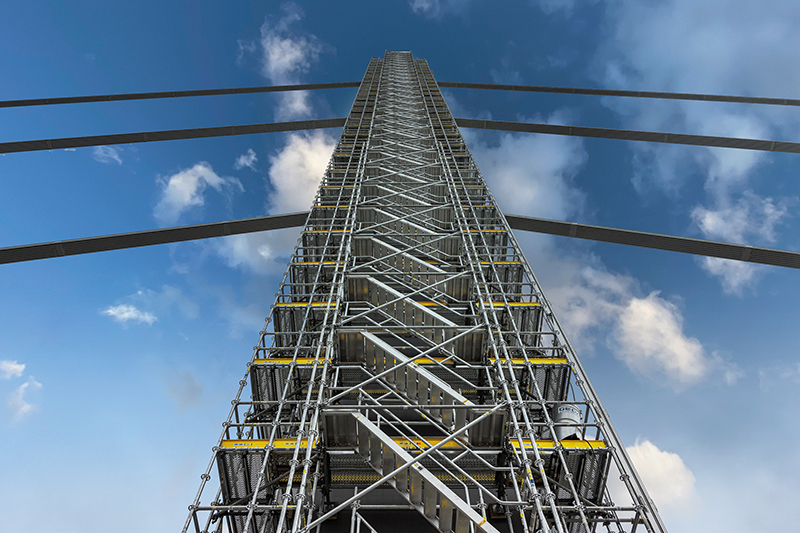

Ringlock scaffolding and formwork solutions in practice at Voest Bridge renovation in Austria

Doka revealed it is adding value by enabling contractors to make intelligent use of its Ringlock scaffolding system to also support renovation projects of all sizes. The recent repair and refurbishment of the Voest Bridge, one of Austria’s busiest road sections on the A7 highway, showcases the modular scaffold system’s capabilities.

Originally built in 1972, the Voest Bridge, spanning the Danube, was the longest in Austria and the first cable-stayed type built in the country. With, on average, more than 100,000 motorists travelling along this section of the A7 Mühlkreis motorway each day, the bridge required maintenance to cope with the constant flow of vehicles. As part of the project, contractor Strabag SE needed to support a 65-metre-high steel pylon without tension anchors. Doka’s solution enveloped the pylon with Ringlock scaffolding, designed to provide a safe and secure working platform at all the levels that allowed for onsite maintenance of the supporting structure.

Doka explained that Ringlock’s high degree of flexibility facilitated the creation of an integrated stairway and connection options to enable the installation of a material lift. Ring-shaped compression struts supported the load, and thanks to the versatility of the modular system, the scaffolding was easily adapted to meet the floor plan’s needs.

Doka’s streamlined services, working in collaboration with scaffolding contractor Pecan GmbH, contributed to the project’s success within the planned three-month timescale.

The manufacturer added that it has played a crucial role since the initial stages of the bridge renovation project, providing formwork for the creation of the temporary bypass bridges that divert traffic into Linz city centre, reducing disruption for businesses, residents, and visitors. By partnering with Doka, Strabag SE and Pecan GmbH benefited from a single point of contact.

According to the World Economic Forum, retrofitting and renovating buildings and structures can result in 50% to 75% less carbon emitted than building an entirely new structure. Doka said it is committed to reducing carbon emissions in the construction industry and is increasing its support for renovation projects.

“The successful application of our Ringlock scaffold system to such an important renovation project as the Voest Bridge demonstrates our innovative spirit, which is focused on improving construction industry standards, enhancing safety and delivering products that reduce the industry’s carbon footprint,” Doka CEO Robert Hauser commented. “We are proud to support renovation projects, as well as thoughtful construction of new structures.”

Doka is committed to achieving net zero emissions by 2040 and provides transparent data on the carbon footprints on more than 7,000 of its products. Robert Hauser said, “Doka strives to support a sustainable future through environmental transparency. In early 2024, we introduced carbon footprint data for our scaffolding products, marking another milestone alongside our formwork portfolio. We are proud to be the first in our industry to do so.

“We believe that renovation projects will comprise a growing part of our business in Europe, and we look forward to working with construction companies to rejuvenate older buildings, revitalise existing structures and repair civil structures that connect communities, just like the Voest Bridge in Austria.”