DOKA was called in to supply a specialised formwork solution to assist with the delivery of a ‘complex’ ventilation shaft, described as a vital element of the landmark HS2 project.

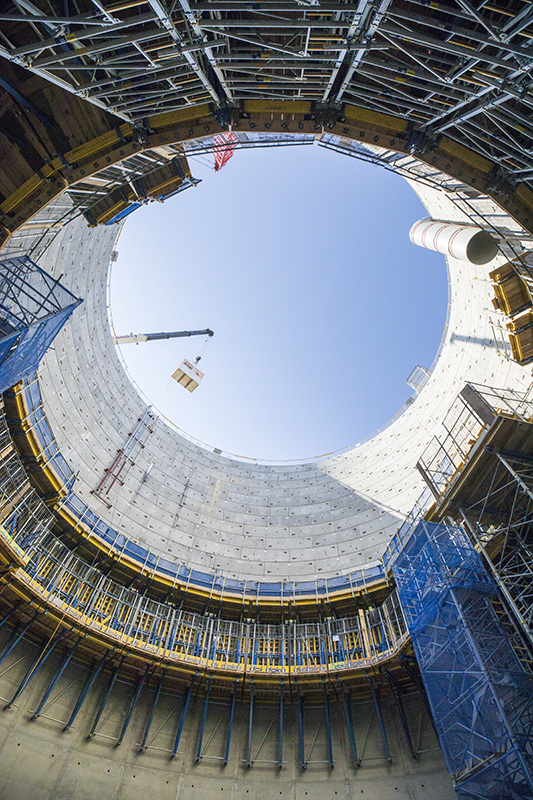

Doka’s solution is for the construction of the shaft secondary lining to the Victoria Road Ancillary Shaft. This section of works is being carried out by Skanska, Costain and Strabag Joint Venture.

The Ancillary Shaft is partially formed by precast rings, while the lower section of the shaft’s wall is also concrete-lined. Doka explained this aspect of the shaft’s composition required the ‘ingenuity’ of the company’s formwork solutions to ensure a fail-proof installation, adding that it was particularly crucial to casting the shaft’s secondary lining which was backed by a waterproof membrane.

Due to the shaft’s 25.1m diameter, the secondary lining was cast in five separate pours to approximately 15 meters above the base slab. Securing the formwork and climbing platforms without perforating the waterproofing during the casting process was one of the challenges.

Doka’s D22 single-sided ‘dam’ formwork was selected for the task. Featuring brackets that adapt to both inclined and radiused walls, the D22 system allows for forming casting concrete without the needs for ties. This, Doka added, eliminates the risk of puncturing a wall’s waterproofing.

Doka’s technical team carried out the necessary calculations to maintain concrete pressures and deflection tolerances.

The concrete casting process was further complicated by three large tunnel openings. Designed for the tunnel intersections, these openings provided an additional challenge as there was no previous walls to attach the D22 platforms. This issue was overcome with Doka’s Staxo 100 shoring system, a load-bearing tower that allows the shoring of floor-slabs of differing layout.

For projects in congested areas such as central London, space is at a premium. Doka revealed it overcame this issue thanks to its pre-assembled panels and platforms. The firm’s site demonstrator made regular visits to advise the installing contractor, SCS JV, on aspects of its formwork and jump system operation. Doka explained the guidance was also invaluable in respect of the company’s Concremote system. The concrete monitoring device uses sensors to measure the temperature and calculate the compressive strength of the concrete structure.

The project’s positive outcome meant Doka was selected to provide the same services for a further four ventilation shafts. This is part of the business’ overall contribution to the HS2 project that includes devising formwork solutions for bridges, tunnels and stations.