Steve Duthie, associate director at Altrad RMD Kwikform, says the future of temporary works’ solutions for road bridge construction lies in sustainable products and processes

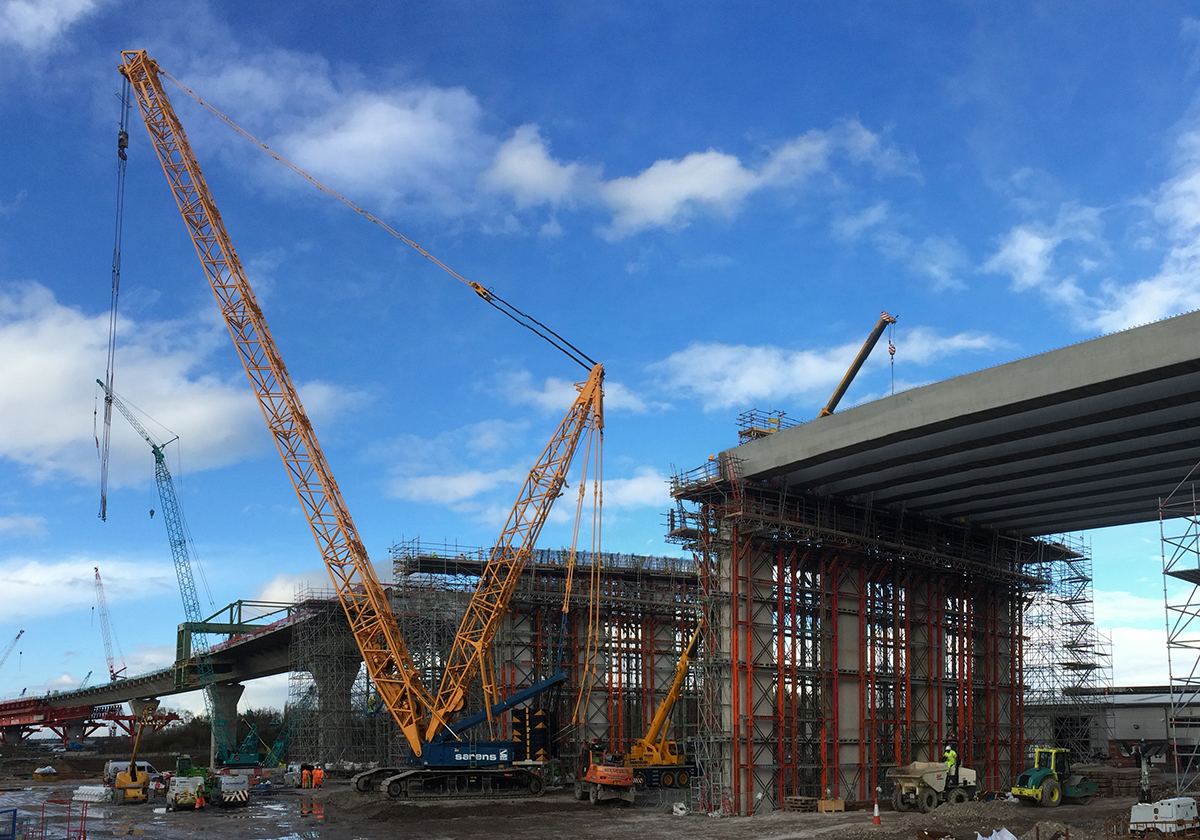

ROAD bridges pose some of the most complex formwork and shoring challenges in construction projects, and sustainability is now forming a key part of the selection process, driven by customer CSR policies, as well as broader legislative requirements.

Greater demands are being placed upon temporary works’ solutions providers when it comes to cost efficiencies, environmentally-responsible material selection and a reduction in preventable waste – in terms of wasted labour and material costs.

This has forced the industry to look at things differently, and determine what features can be incorporated into products and processes to help infrastructure contractors with their environmental responsibilities. With this in mind, ARMDK is leading the way with value engineering, ingraining sustainability into its operations and equipment.

Innovative equipment design

Products are designed to be as economical as possible; in terms of the physical cost of hire and in reducing overall carbon footprint. Through innovative digital engineering techniques, the required road bridge structure is designed, prioritising the use of the least equipment possible, without compromising on structural integrity during the project.

The benefits this offers include fewer deliveries required to site, resulting in less transportation and delivering a lower overall carbon footprint, alongside reduced haulage costs. To put this into context, the Rapidshor heavy duty galavanised modular steel system uses a third less equipment than equivalent options on the market, to achieve the same strength-to-weight ratio. The result is a significant reduction is assembly times, less site equipment and labour costs, resulting in faster project turnaround times.

Bridge construction equipment is also designed to help improve site speed and labour times. For example, completing projects in a faster timescale enables further environmental improvements; in short, less time on site means less requirement for ancillary equipment such as diesel-burning generators or plant machinery, helping lower costs further.

Furthermore, Paraslim Safetie is a flexible modular cantilever formwork system designed to facilitate the construction of deck edge projections, parapets and string courses for composite bridge decks constructed with steel girders or precast concrete beams, making it ideal for road bridges.

It can be lifted in on beams, so on an overnight road possession, the bridge structure can be constructed, and the road opened fully the next morning to ease the flow of traffic. In most instances this can be completed in one night, in comparison to closing the road for as much as a month.

The option of hiring equipment rather than purchasing offers a more sustainable option, meaning the kit can be used on site and then returned for use on another project. In instances where the equipment is purchased – for example, a project with a long lead time where the temporary works solution will be required for many months – it can be more cost effective to buy rather than hire.

Sustainable components

On road bridges, all temporary works’ components are manufactured from either steel or aluminium, so once their lifecycle is over through damage or wear and tear, they can be recycled. Reusability is also prioritised wherever possible- for example ties can be rented, reducing customer costs considerably.

Equipment should also be designed to last, and certain systems such as Megashor and Superslim Soldiers have been used for up to 40 years and are still performing excellently.

A more recent development is the switch from using plywood for decking panels to Alkus panels – solid plastic formwork panels made from aluminium reinforced polypropylene, enabling up to 1,500 uses with just one panel, meaning less re-facing.

Alkus lasts longer and is better for environment, eliminating the use of plywood that is impregnated with chemicals. It is also less wasteful, as the Alkus decking is reused and not scrapped as the plywood was previously.

Visualisation software

Construction software can also enable more sustainable operations, and solutions such as our Locus Eye offer high quality interactive 3D models of temporary work schemes. This provides a vital means of viewing and interrogating a temporary works solution during the pre-tender or build phases of a project, and reducing on-site risks, as any potential issues can be seen quickly.

It also streamlines work processes, as the overall system and individual products can be viewed in an accessible and user-friendly format. Before the emergence of construction software, bridge design engineers would previously have to count every single component part – sometimes in their thousands.

Software can now generate a list, with the press a button.This enables engineering teams to move onto more value-added tasks, far quicker, and there is no need to supply extra equipment or extra components to account for human error. Accurate picking lists can be created, and the precise schedule as generated by the engineering team can be followed.

There is less wastage, and additional cost savings from shipping less kit too – all adding up to previously unseen time savings, process efficiencies and cost reductions.