Thanks to advancements in digital engineering, more concrete contractors are benefiting from being able to plan and explore their project in a 3D digital environment, before they reach site. Here, Billy McCormick, Mabey Hire’s head of regional engineering – north, explores how working with a temporary works specialist and the use of BIM can contribute to a more successful formwork delivery.

AS with all temporary works, formwork panels and falsework props are only installed on site for a short period of time. Yet, despite this, they can have a very real and long-lasting impact, with the success of the concrete pour – and indeed the overall project – often heavily dependent on the initial formwork scheme design. Given this, it’s clear that BIM can deliver real value to this stage of a concrete project, right from the initial tender, ensuring an accurate bid, through to on-site delivery.

Entering the digital world

In many ways, the 3D digital environment enabled by BIM is central to ensuring a successful formwork delivery. While its use is perhaps more commonly associated with permanent works, designing and visualising a project’s temporary works in this 3D digital environment can provide similar rewards.

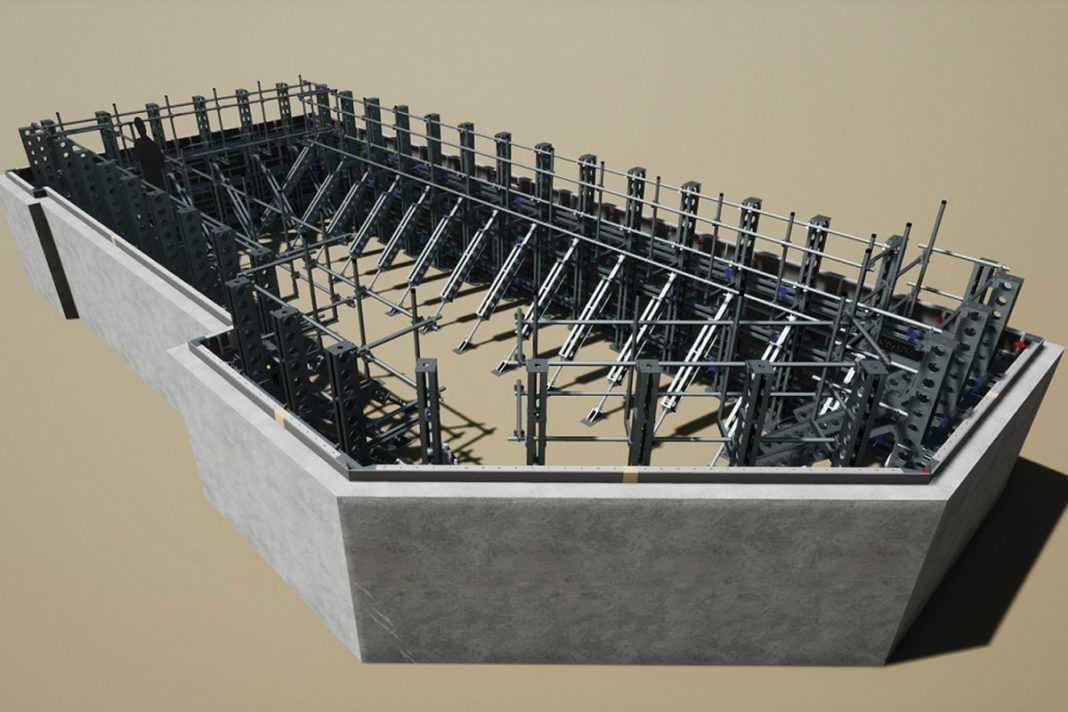

When working with a temporary works specialist with BIM capabilities, you can either provide 2D drawings for the temporary works engineers to first model in a 3D environment, followed by the formwork scheme; or, if your company also has BIM processes and workflows, a 3D model of the permanent concrete structure can be provided for the formwork and falsework to then be designed around.

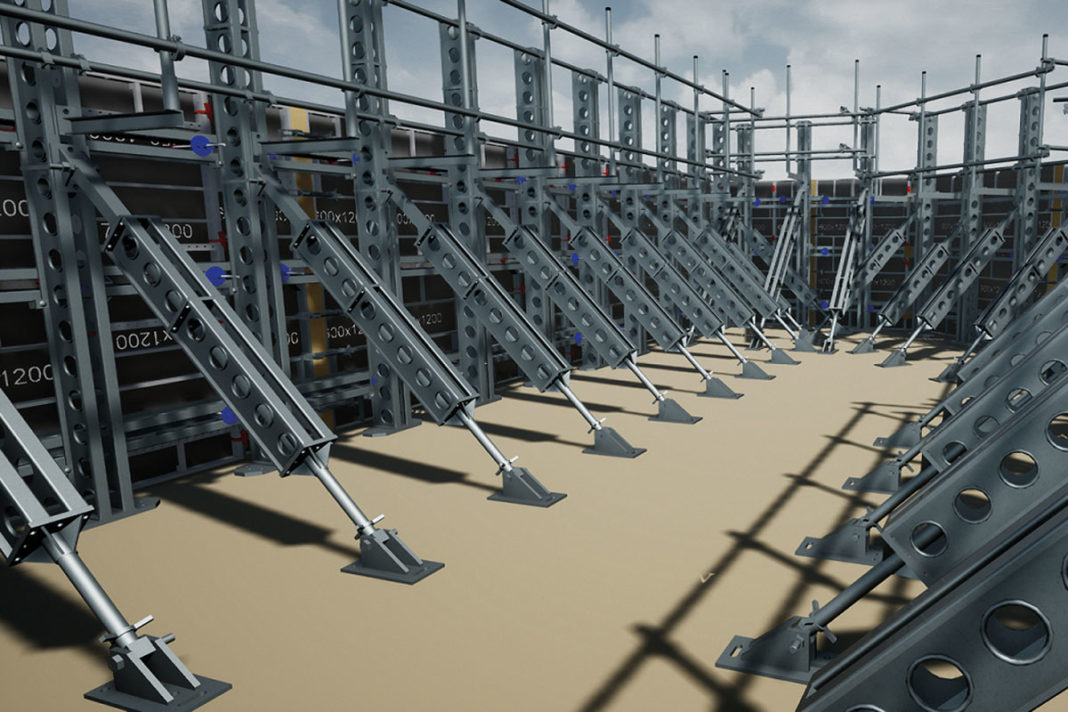

Through the use of intelligent BIM software (such as Revit) to model and visualise the formwork scheme, the likelihood of design issues or rework being required on site can be reduced, with features such as clash detection helping to ensure that the proposed formwork is both correct and constructible. Not only this but moving from 2D to 3D can also enable more complex geometry – such as curved concrete walls – to be created, with the temporary works specialist and contractors able to more effectively visualise and plan the formwork scheme required to bring the end-vision to reality.

Designing more efficiently

As well as improving design accuracy and helping to facilitate the complex, BIM can also help to enhance the overall formwork scheme’s efficiency by reducing the amount of steel props, frames or supports needed.

Through the use of a 3D digital environment, temporary works specialists are able to model, analyse and consider multiple formwork design iterations with a level of certainty that simply wouldn’t be possible in traditional 2D. This allows engineers to select the design that strikes the optimum balance between performance and steel weight. Put simply, the fewer components used, the lower the cost. Not only this, but fewer components can also result in time savings, with the formwork and falsework being quicker to assemble and disassemble on site.

Build it, before you build it

It can be said that BIM offers a digital rehearsal of the temporary and the permanent works, before you get onto site. Effectively, it allows you to build it, before you build it – a more sustainable approach that has the added benefit of saving labour, time and cost.

Being able to see the whole formwork scheme and phased concrete pours in the context of the overall project or construction sequence will not only aid better delivery of the works but can also improve coordination and communication between project parties. Once a 3D model has been created of the temporary formwork scheme, this visual tool can be shared between all parties and disciplines, from the installer and concrete contractor to the site manager and client.

Liaising with a temporary works specialist with immersive technology capabilities, as well as BIM processes, takes this one step further, enabling teams to be taken on an immersive journey of their project.

While only temporary in nature, formwork and falsework schemes have an integral role to play when it comes to a project’s permanent concrete works, with any mistakes, clashes or delays at this stage potentially having a significant impact further down the construction sequence.

With this in mind, collaborating with a temporary works specialist with BIM capabilities can provide you, and your client, with numerous benefits and assurances. As BIM becomes firmly embedded in construction’s permanent works, designing and visualising a project’s temporary works, such as formwork, in this same 3D digital environment is surely the next step.