A modular steel construction system developed in Scotland has been included in an investment programme to be delivered by the US Department of Energy (DOE), which aims to explore innovative construction technologies to help reduce the cost of new nuclear builds and speed up their development.

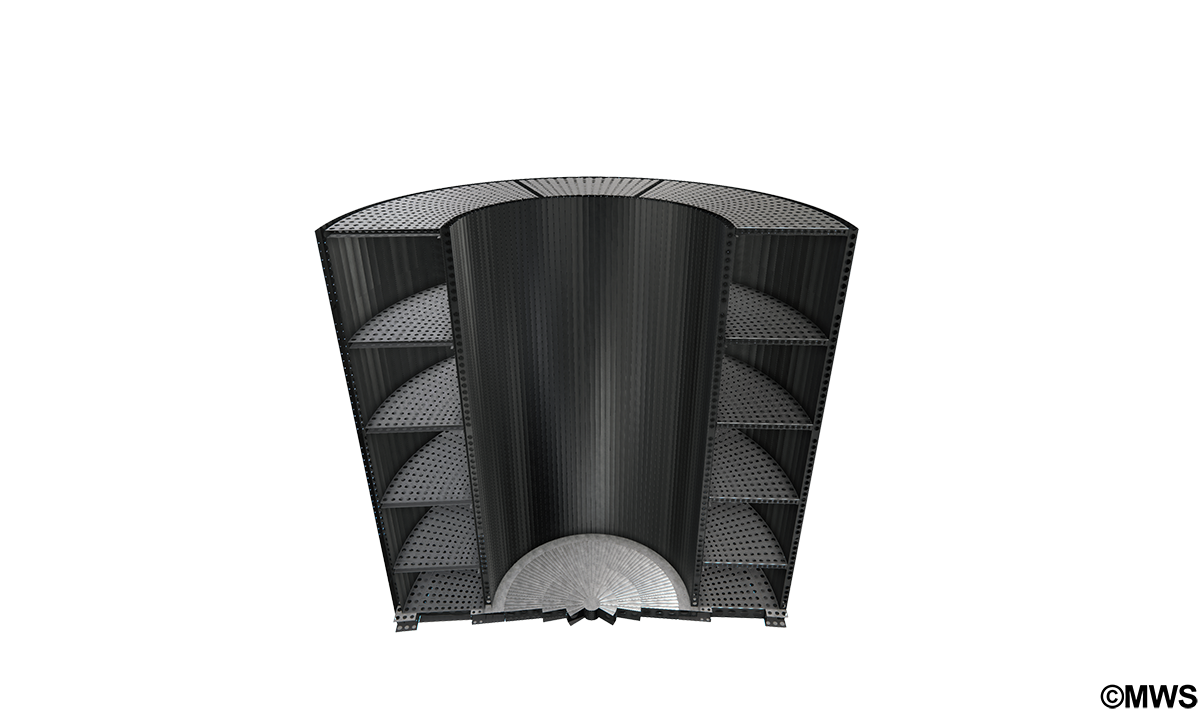

Steel Bricks was developed by Renfrew-based Modular Walling Systems and is fabricated by Caunton Engineering at the company’s Nottingham HQ. The system has been described as ‘high-tech LEGO pieces’ which could reduce the amount of construction labour required to build nuclear reactors on-site.

The Steel Bricks system is one of three projects that will be funded by the US DOE’s Advanced Construction Technology (ACT) initiative. GE Hitachi Nuclear Energy lead a team to explore technologies from other industries. Steel Bricks was recently identified as a major component for GE Hitachi’s BWRX-300 Small Modular Reactor (SMR).

Simon Bingham, executive chairman for Caunton Engineering, said, “Our 10-year collaboration with Modular Walling Systems to create the Steel Bricks system has established a ‘first of a kind’ concept in the fast-emerging world of steel composite construction. The system provides not just the walls and suspended floors or roofs in steel composite, but most importantly a basemat. This takes away the need for conventional foundations, eliminating the traditional Achilles’ heel of this form of construction which are the weak points of the basemat to wall connection.

“Many attempts have been made during the past 25 years to devise simple, safe and rapid fabrication methods to internally connect steel faceplates. But most have lacked commercial application due to being too expensive and labour intensive. We can now successfully deliver a solution which is technologically proficient whilst providing significant cost and time saving benefits.”