BAM Ritchies, the ground engineering and geotechnical division of BAM Nuttall Ltd, has revealed details of its key role in a project in a controlled highway environment in the heart of Glasgow.

The new Sighthill combined cycle and footbridge is being constructed by BAM Nuttall on behalf of Glasgow City Council and will be a gateway feature over the M8 motorway. The bridge is designed to provide a safe and attractive link from the redeveloped Sighthill area to the north of the motorway into the amenities of Glasgow’s bustling city centre.

BAM Ritchies explained that digital construction tools were used extensively to model the site and proposed operations during the pre-construction phase. This included the development of digital 3D and 4D models which remained live and updated throughout the construction phase to reflect dynamics in delivery strategy. This allowed the site teams to ‘build it before we build it’ and identify opportunities for improvement and mitigate risks at each stage.

BAM Ritchies was tasked with delivering a wide range of works including ground investigation (to optimise the pile design), pile design detailing for bridge abutments and retaining walls, drilling and installation of 109nr piles up to 1200mm diameter installed using rotary techniques, and UKAS validation of pile quality and integrity on completion of installation.

The company said its risk management strategy started with the design and delivery of ‘intelligent’ ground investigation. By ensuring a targeted ground investigation was undertaken, BAM Ritchies revealed it was able to inform the initial design decisions and validate assumptions made in the early stages of the project.

The firm’s integrated solution directly linked the ground investigation and piling teams, which was said to streamline the ability to deliver all aspects of the ground engineering works including procurement and management of ground risk. This ensured delivery of piling operations were planned in detail and could be visually demonstrated and optimised in advance of mobilising to site.

By adopting digital processes, BAM Ritchies added that it eliminated paperwork from the ground investigation discipline. The digital approach ensured 100% data capture and validation in accordance with the specification. Digital data capture enables ground investigation data to be produced and shared more rapidly. At Sighthill, borehole records were produced within 24 hours of a borehole being completed, allowing draft ground models to be produced ‘rapidly’.

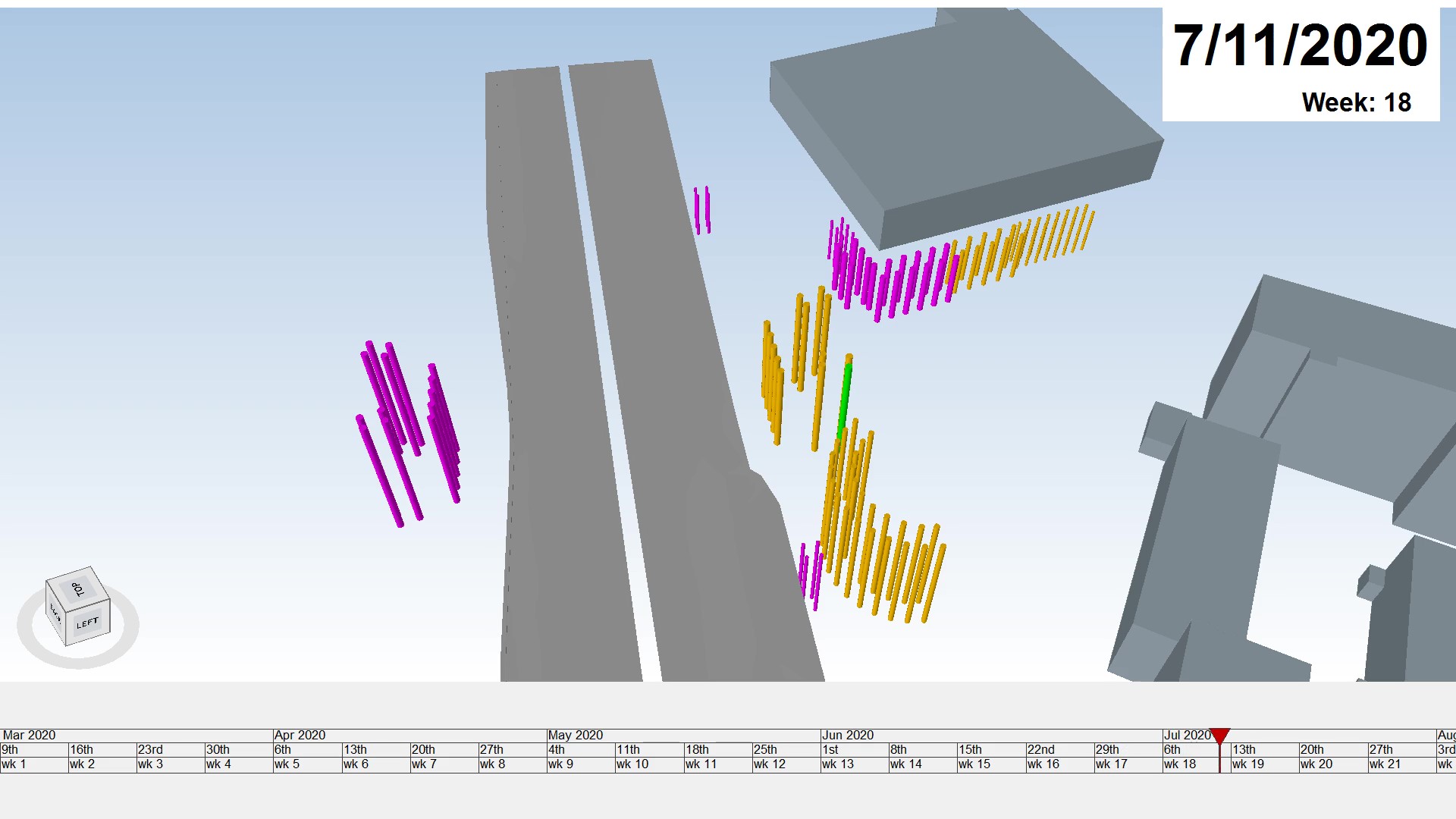

Following the ground investigation works, the digital journey for the construction phase started with the project team preparing a 3D model for the project and combining the model with the programme to create a 4D animation. The model was augmented by adding plant, equipment and materials storage areas which allowed all stakeholders to collaborate optimising the size of the working platforms for each stage. During the digital rehearsals it was identified that due to the physical restrictions of the site and the adjacent motorway, pile cages would need to be installed in sections at some locations. This prompted the use of the Superlatch system, which BAM explained ensured a ‘premium splice’ whilst eliminating hazards to personnel normally associated with pile cage splicing.

The 4D piling animation was used by the BAM Ritchies and BAM Nuttall delivery teams to identify the optimum piling sequence.

During piling works, borehole logs and quality records were captured on iPads and automatically linked to the 3D as-built model. This allowed records to be shared in real time with both customer and designer. Colour coded 3D models could also be quickly created from BIM 360 Field to monitor progress and highlight where contribution from the designer or support from Bam Nuttall was required to maintain or improve progress.

BAM Ritchies revealed pile integrity and quality was demonstrated using ‘multiple’ techniques to build a database of evidence. During drilling, an on board rig data collection system was used to ensure correct termination depth was achieved for each pile. A video inspection of each borehole was then undertaken prior to concreting. Again, this information was linked to the 3D model and shared with the client and designer. This allowed remote approvals to be given which proved critical during Covid restrictions.

Prior to concreting, fibre optics cables were affixed to the pile cages and embedded in the pile which allowed monitoring of temperature profile over the full length of the pile. This, BAM Ritchies added, allowed ‘quick, transparent and detailed’ analysis of integrity of the pile while the concrete cured over the first 48 hours.

The firm’s UKAS technicians and laboratory also supported the M8 scheme to ensure that piles were right first time, 100% validated and conformed to the specification. The technicians provided further guidance to BAM Nuttall around concrete quality control and testing and also validation of piling platforms.

BAM Ritchies said pre-construction works combined with 3D and 4D modelling allowed the firm to:

• Plan and undertake a ground investigation that reduced ground risk to the project

• Ensure predictable performance by challenging the delivery sequence and plant selection in a digital environment

• Reduce vehicle movements and optimise resources – improving safety and reducing carbon footprint

• GPS setting out direct from the model to reduce error

• Rapid, transparent sharing of information with all stakeholders to aid collaboration and progress project delivery

• Collation of quality data to allow all records to be collected, reviewed and retained for future reference

By combining these elements, the company explained it was able to plan and deliver a project that supported the development of a critical link which will enhance the environment and improve the quality of lives for the residents of Sighthill and the surrounding communities.