BEAVER Bridges, the firm which will reconnect Lossiemouth with its iconic East Beach in a £1.3 million project, has revealed it wants to go further than just building a bridge in the town.

The company, which has a base in Glasgow, secured the contract from Moray Council for the bridge build after the Scottish Government backed the project with funding.

It comes after the original Lossiemouth East Beach bridge, which acted as a crossing over the River Lossie to the beach for over a century, was forced into closure after a survey found it to be leaning to one side. Prior to this, studies revealed that some 4,000 people used the bridge per day in the summer months – with 72% of local businesses reporting a loss in trade since the beach became inaccessible.

Peter Dalzell, executive director at Beaver Bridges, told Project Scotland that the whole community relies on the bridge as the only route to the beach and as a result there is a great deal of interest in the project. “Engaging the whole community is key to us and bringing in schools is where we can have the biggest influence,” he said. “If we can get kids interested in the sector alongside the build – even if it’s just a few – then it’s a job well done.”

The firm has strong links to Lossiemouth, with MD Henry Beaver having attended a nearby school and his wife Jo being born and raised in the Highlands before qualifying as a chartered accountant and specialising in manufacturing and construction audits. She now acts as financial director at the company. Jo has close family in nearby Findhorn, Nairn and Burghead. She told Project Scotland of the fond memories she has of the Lossiemouth beaches and the impact the East Beach bridge has on the local community.

Founded in 2016, the firm has designed and built bridges across the UK and told of the ‘great pride’ it has in its strong presence in Scotland due to its family links. Projects include the creation of a new pedestrian footbridge at the Union Canal, the build of a vehicle bridge at Canglour Glen, numerous wind farm and forestry access bridges across the Highlands and a footbridge over the South Tyne in Northumberland.

Jo described securing the Lossiemouth project as “very significant for the company”, before revealing her hopes that the firm’s own inclusivity – with many females occupying senior roles and its oldest employee being 78 and youngest just 16 – will inspire local children to consider a career in construction. School visits and pupil opportunities are planned, should Covid restrictions allow.

“The fact that I am a woman (in this industry) does have its challenges which I am pleased to say are getting better, but I’m very much of the view that you can do whatever you want, if you work hard enough,” she said, before telling of how the firm recently promoted a female employee to operations manager, just four years after joining the business with no prior construction experience. She is also proud of leading by example to her two little girls and proving that every career opportunity is open to them.

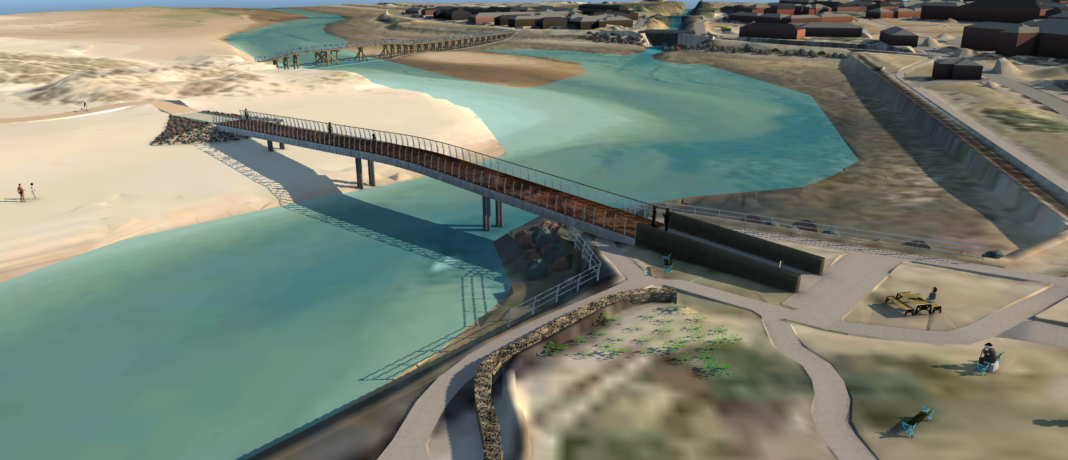

The build itself is sure to attract interest, given its complex nature. A specialist marine contractor, with experience in offshore infrastructure, has been brought on board to mitigate some of the risks faced when working in such a harsh environment. The bridge will be located at the town’s esplanade. Building it at the nearby site of the original bridge would have seen an estimated project cost of £2.2 million due to the distance between the crossing. Further to this, there would be temporary pauses in construction due to sea defences being compromised.

Surveys have shown the chosen site to be ‘marginally more’ exposed to the ocean sea, with the area’s seawall noted to be in a ‘poor condition’. However, Luke Jenkins, senior engineer at Beaver Bridges, said he is confident the build will go smoothly and as planned.

Key to the project will be the fluoropolymer paint system to be applied to the steel structure of the bridge. “Durability is a key point in the project,” Luke said. “This coating, I believe, will become standard in the very near future – more and more projects are adopting it. It has a predicted life of 60 years with the first coating. In a particularly harsh environment like this, where using steel, that coating should ensure a very durable structure. Ongoing maintenance will be extremely economical.”

He added that a composite decking board will be used, as well as parapets made from rigid steel posts with tensioned standstill steel wire infills – allowing for a shallow cross section to the bridge. Luke said this will ensure that, in an unexpected flood event, the design will allow for the water to flow through without causing any notable damage. “If it does affect the parapet, it will just be a case of replacing or simply re-tensioning the wire infills” he explained. “We’re focussing on durability, ease of maintenance and also an aesthetically pleasing structure.”

Construction work is expected to start shortly, with an estimated completion date of Spring 2022. An economic study funded by the Lossiemouth Community Trust revealed that the difference in visitor spend in the town between replacing the bridge and not having it is £1.5 million per annum, meaning the cost could effectively be recouped by the local community within a single year.