Most construction businesses have similar priorities — deliver high quality work to the client’s budget and deadline. Investing in technology can enable companies to complete jobs more quickly and accurately, helping them to meet client expectations. For example, global engineering consultancy, Arcadis, found that when using a drone, it could complete surveys ten times faster than traditional topographic surveys. Here, Carl Parsons, regional sales manager at SITECH UK & Ireland, explores the benefits of drone surveys and explains how to effectively introduce a drone onto a construction site.

MANUAL surveying and data collection can be a time-consuming process. For example, a three-to-five-acre site can take days to survey. Traditional surveying techniques will only provide a limited number of points within the same time frame, giving an accurate, but potentially limited overview of the site. Large data sets can also be hard to present in an understandable way that fits the client’s needs. If customers want weekly updates on the progress of the site, it can be time consuming to repeat the survey to collect the comparative data.

Traditional surveying can also create health and safety issues. During a survey, engineers are frequently walking between large pieces of equipment and climbing on unstable stockpiles, such as quarry material, putting them at risk. Recent improvements in drone technology have provided new opportunities for the construction industry to conduct surveys safely and effectively. As long as the drone operator can see the drone, the surveyor can be in one static and safe position on site.

Introducing a drone

There are two ways to introduce a drone to a site, the first solution is to train someone in the business to become a drone operator. Three-day training courses offered by construction technology specialists, such as SITECH, teach some simple manoeuvres and educate operators about regulations surrounding commercial flying, such as completing a logbook and informing local airports. Operators will receive a drone pilot licence at the end of the course.

The alternative solution is hiring an experienced drone operator who can carry out drone surveys immediately, rather than waiting for employee training. Hiring can also be a short-term solution for construction business to test the waters and see if drones are useful for their projects before investing in training. Site managers can approach construction technology providers, such as SITECH, as a one stop shop for drones. Our experts can supply the drone, set it up and explain how to effectively use the data collected. After this initial investment, site managers can begin to use drones in all large projects, leading to more surveys and improved data analysis and communication with customers.

Collecting data

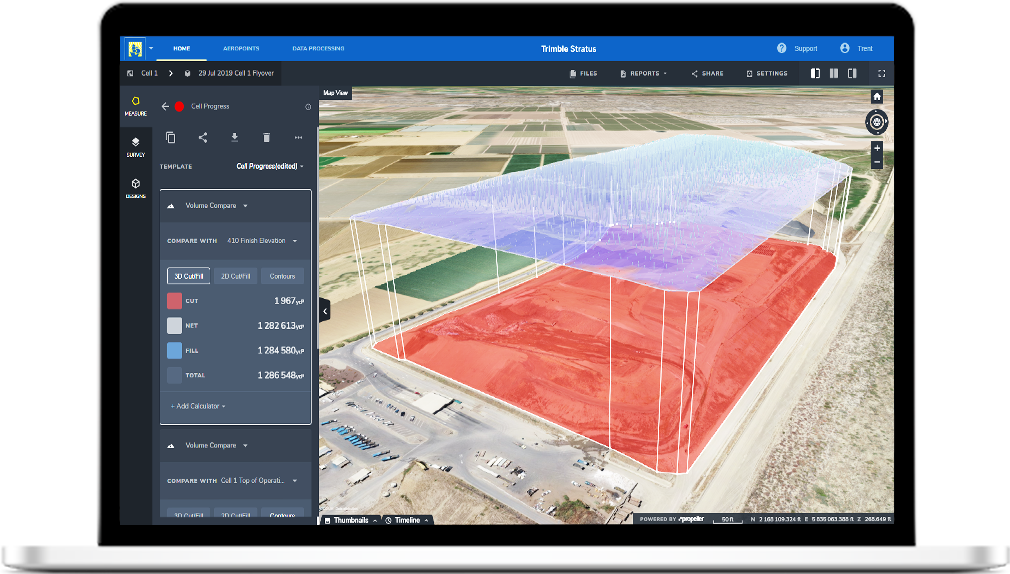

Using drones to collect a large amount of data appears useful, but construction companies must know how to effectively analyse and use collected data to benefit themselves and the customer. Integrating data collection software, such as Trimble Stratus and Trimble Business Center, allows construction businesses to provide 3D cut and fill data, so the customer can easily track the project against the design.

Customers can also annotate the data and manipulate the software themselves to get print outs of volumes or cross sections of stockpiles, to share progression with stakeholders. For certain customers, businesses will need to package the data in a specific way to show particular points, such as the amount of stockpiled material in cubic metres. Data collection software allows quick changes to be made to data presentation, rather than making a surveyor reproduce everything.

Compared with manual data collection methods, drones can improve site safety, increase the number of data points and provide customers with a better understanding of their construction site. Drones can help to reduce waste caused by human error and decrease surveyor time on site, which can lower costs by approximately 50%. While drone technology may be a costly initial investment, it enables construction businesses to improve their productivity, reduce mistakes and more easily meet a customer’s expectations.