INVERURIE-headquartered Scotframe has set its sights on the growing demand for timber frame housing in England with a series of new appointments and business plans.

Sales director Malcolm Thomson told Project Scotland how the firm’s solid foundations in Scotland have left the business well prepared to target the market south of the border.

Scotframe has almost 200 employees, a turnover of £38 million and is now part of the Saint-Gobain group.

Having supplied housebuilders such as Cala and Tulloch Homes, the firm opened its first showroom in England two years ago, in Swindon. To support growth in the English market – both amongst SME housebuilders and the private self-build housing sector – Scotframe recently appointed Andy Lewis, who has worked in the timber frame sector for 15 years, to the newly created role of business development manager for central England.

While the majority of new homes across Scotland are timber frame, the English market has been slower to embrace this method. However, with factors such as sustainability and offsite manufacturing becoming more pressing, that is gradually changing.

Malcolm Thomson explained, “England is quite a bit behind in the use of timber frame. It is still used but not as predominantly as it is in Scotland.

“83% of new builds in Scotland are timber frame whereas in England it’s down at 23%. It’s becoming more popular; it’s still a popular choice for self-building (but) maybe less so for volume housebuilding.”

In 2017, the UK Government set a target of building 300,000 affordable houses by the mid 2020s. Malcolm added, “They’ve realised they’re not going to manage to do that with traditional methods so offsite is a method that has been pushed forward as a means of achieving that.”

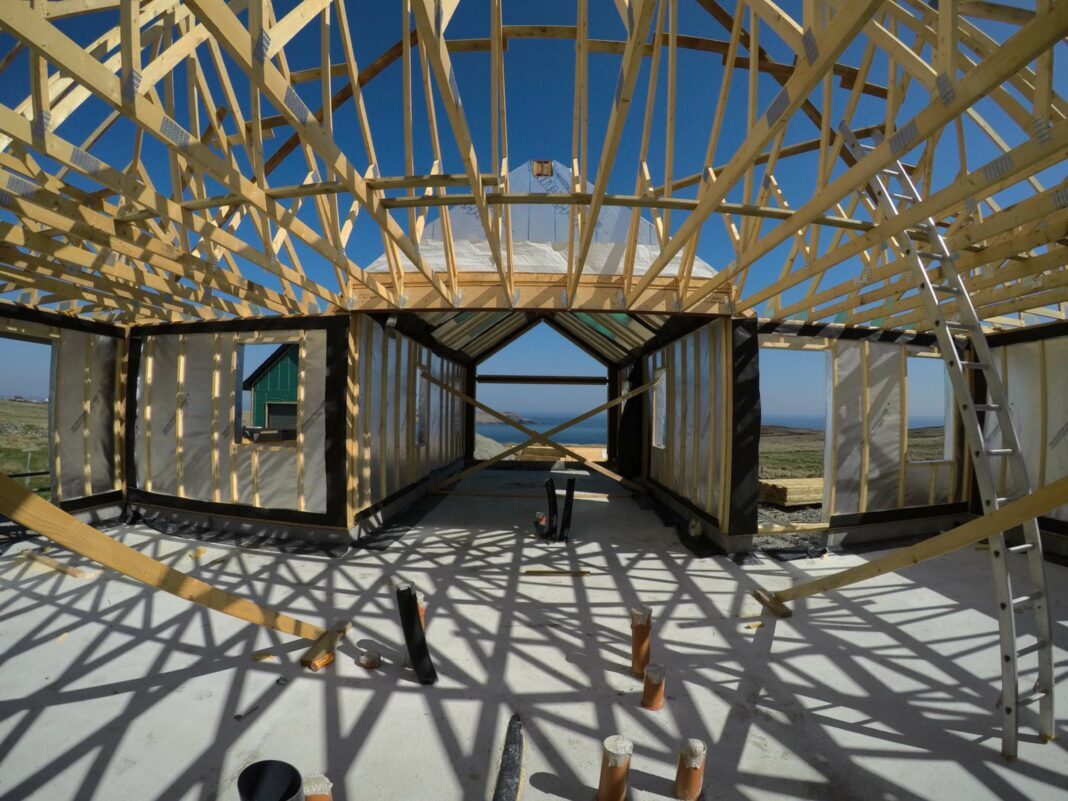

Energy efficiency, according to Malcolm, goes ‘hand in hand’ with timber frame build. Scotframe has a fabric first approach, whereby they ensure the fabric of the building is as energy efficient as possible. The firm’s Val-U-Therm Plus system is billed as building on ‘the best aspects’ of timber frame, such as the already enhanced insulation through the air tightness of this method of building.

Using wall, floor and roof panels, the firm said it delivers an ‘exceptional’ thermal performance with ‘class-leading’ environmental and sustainability credentials.

With Scotframe supplying more full kit timber frame packages to self-builders than any other firm in the UK, Malcolm said the company’s previous operations in England and Wales means it is an easier job breaking into these new markets.

“Within the last couple of years, we established our base in Swindon at the National Self-build and Renovation Centre. We now have three business development managers covering key target areas in England, including Andy Lewis based in the Midlands who joined in February. So, we now have dedicated people and we see us establishing that extra showroom space to support those people so customers have a place to go and see the product, touch and feel it – which from a self-build point of view is crucial.

“In addition we also see digital playing a far greater role in supporting our customers, and we hope to incorporate interactive solutions into our business and showrooms in the near future.”

Malcolm emphasised the importance of customers having contact with Scotframe employees who are local to them and available to offer assurance during the various stages of the self-build process, including the ability to visit sites.

“Self-build is definitely important – it’s approx. 50% of our business from a value point of view – but it’s not our only focus,” Malcolm added. “I think what we can offer customers is that we’ve got 30 years’ experience; we’ve got a supply chain that’s been around us for most of that time; we’ve done on average around 1,000 houses a year. We’re a full kit package company – so we don’t just provide structural elements of the timber frame. We offer our customers support right from the outset of the design of their building, through the planning and building control process and also provide them a tailored specification that meets their own specific needs and budgets.”

Despite aspirations for growth in England, Malcolm insists that work is still being put in to improve the operations across the board. The business is aiming to bring new products to the market and enhance customer service still further.

“We’ve recently appointed a technical development director who will not just sell products but also our processes and systems,” Malcolm said. “I think the appointments are crucial, for both the self-build and volume trade customers. From a self-build perspective, just having someone at the end of the phone who is local is crucial.”