Priscila Escobar, design manager from HAKI, explains why it is important to utilise simple systems to create the most complex of scaffold designs

IMPLEMENTING a scaffold system for complex structures such as bridges, power plants, and oil refineries is no easy feat. These high-level projects require fast deliverables to complete the job on time, and there are lengthy processes which need to be followed to ensure projects are delivered safely and to multiple standards, such as BS 5975:2008 ‘Code of practice for temporary works procedures and the permissible stress design of falsework’ and BS EN 12811-1:2003 ‘Temporary works equipment – scaffolds – performance requirements and general design’.

Designing temporary access systems

The demands and pressures of a complex project do not have to weigh heavy on its supply chain, as there are measures which can be adopted to keep things simple. Let’s take an oil refinery in the North Sea or a suspension bridge in central Scotland. Subcontractors need to have access to parts of the site which can be potentially hazardous, meaning they may require specialist temporary access or scaffolding to reach new heights safely.

But in order to assure safety, safe and effective solutions should be engineered to allow maximum efficiency once the project commences. This involves a great deal of proactivity and cooperation from the project’s entire supply chain, which begins at the design stage.

Creating the right scaffold or access design is a collaborative effort from the beginning. Customers are requested to be as specific as possible with their engineering, safety, and environmental goals, in order to formulate a strong design brief.

It is imperative that companies such as the likes as HAKI listen to their clients and ask essential questions throughout the early stages. This will establish a coherent understanding of the required outcome, to ensure HAKI gives its customers the solutions needed to make the project a success.

Working collaboratively, therefore, prevents any hidden challenges from emerging. It is why the HAKI design team gathers as much information as possible from the customer; particularly clear images or drawings of the real-time location. This gives designers a holistic image of the job at hand, and will mean many obstacles are removed from the design stage.

To make sure designs can transfer to the site, designers collaborate with in-house technicians to ensure suitable components are chosen. Although a designer might need a 6m length beam, it might prove difficult for the subcontractor to handle! In this case, the installation technician would request designers use 2 x 3m beams connected to make construction easier.

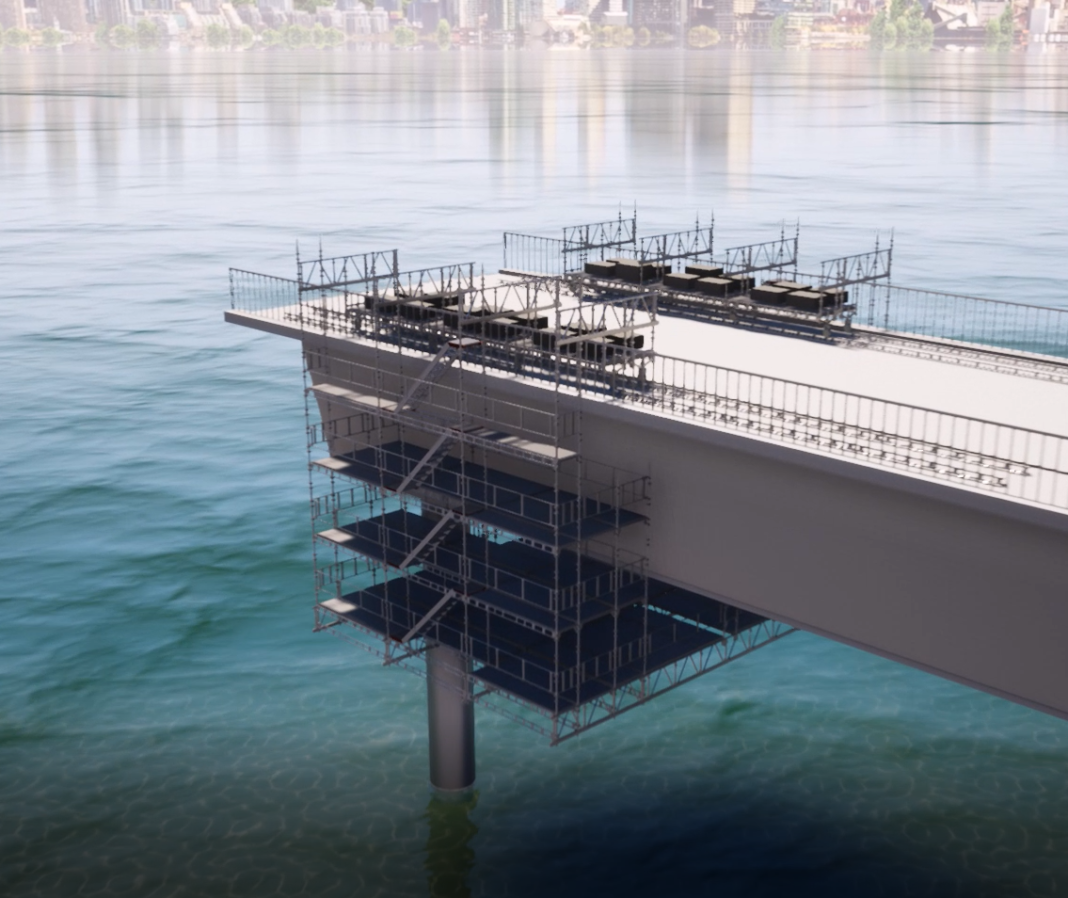

The adoption of digital technologies such as BIM further enable complex projects to be made simpler. By sourcing high-quality 3D models and information of permanent structures from the outset, assumptions in the design stage can be avoided and accuracy can be guaranteed. Scaffold designs can then be created for the structure using the HAKI BIM module in Autodesk Revit, where all the individual components can be seen.

Whilst delivering repair works on the world-class Forth Road Bridge, central Scotland, HAKI-owned company, Span Access Solutions, utilised BIM to engineer a flexible, quick-to-install suspended access solution. As well as assimilating a model, BIM subsequently allowed the client to see the proposed solution in virtual reality prior to the project’s start-date.

To give added flexibility, a HAKI BIM model can be reviewed by various project stakeholders in Autodesk Viewer, where they can discuss and suggest relevant changes easily. This will then ensure what is ‘as-built’ translates to the real-time building.

In terms of logistics, HAKI believes it is always worthwhile to send extra material if the projects are in restrictive areas.

Simplified, lightweight, prefabricated components make it easier to transport to challenging locations such as offshore rigs. To keep things simple, experienced technicians are onsite to supervise a complex scaffold structure if the customer requires the support. Training can also be an option, to ensure installers are confident when handling the scaffold equipment.

Case study: Hinkley Point C

When it came to delivering the temporary access systems for Hinkley Point C’s west pool bunker, consideration had to be paid to the level of protection required and the compatibility of both the temporary and permanent works. As a result of the project’s complexity, multiple iterations of the initial design were considered to ensure its simple design complemented the intricate requirements.

HAKI’s dedicated team tailored a solution using its HAKITEC 750 and HAKISPAN products, designed by scaffolding engineers, 48.3. Measuring 35.5m long and 33.97m wide, the 750 weather protection roof is a highly robust and easy-to-maintain solution which enables the optimum working conditions for construction work to be undertaken efficiently and safely. On this high-profile project, the temporary access solutions ensured HAKI covered all the bases.

Utilising a scaffold system for a complex structure might feel like venturing into uncertain territory. Yet, by working collaboratively with customers from the design stage, specifying the right products, and embracing technical support when required, the most complicated of projects can be made simple, making for a design which performs well and assures safety throughout the project’s lifecycle.