Meticulous co-ordination keeps task on track

ONE of Scotland’s busiest railway stations, Aberdeen Station, is also an important architectural landmark with a ‘Category A’ Historic Environment Scotland listing, so maintaining the building is vital for both operational and conservation reasons.

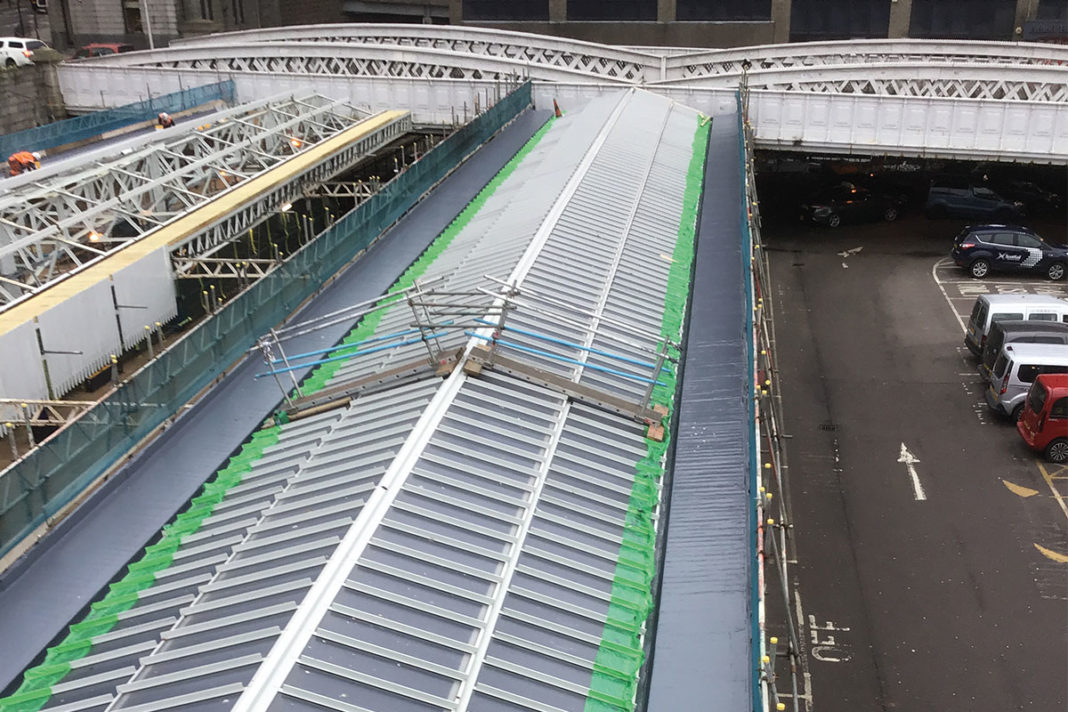

The station building has a glazed canopy roof, which was in need of a full upgrade. This included replacement of the glazed roof area, along with waterproofing of the gutters, located around the perimeter of the canopy, and of the plinth that connects the gutters to the glazed roof, forming the base for all maintenance walkways.

Sika’s roof refurbishment team carried out a full survey of the roof and the Sika Liquid Plastics Sikalastic 625 cold-applied liquid waterproofing system was specified for the project.

Roofing contractor Everlast (Rail) Limited delivered the roof refurbishment, working closely with the glazing contractor and principal contactor, Story Contracting, to plan the project around the operational constraints of the station and the sequencing of each element.

Ideally, the existing glazed canopy would have been stripped out first, making the task of refurbishing the roof easier to programme and manage on site. However, the two elements of the project were carried out simultaneously to reduce the project duration. Platforms remained in use throughout, so strip-out and reinstatement of the roof/gutter areas were co-ordinated to minimise disruption to the public and avoid water ingress.

The glazing was carried out overnight and the Everlast team co-ordinated with the glazing contractor and Story Contacting each morning and evening to schedule activity and ensure no glazing operatives disturbed freshly waterproofed areas.

The existing felt, which ran from the adjacent deck section, was stripped out from the cast iron gutters and the metal surface was prepared prior to application of Sikalastic Metal Primer, followed by application of the Sikalastic 625 cold-applied liquid membrane. The Sikalastic 625 system is said to have provided the versatility needed for dressing the new roof covering to the shape of the gutters, and was also viscous enough for application on vertical surfaces.

The existing felt covering was also stripped out from the plinth areas on a phased basis to co-ordinate with the glazing works. Sika’s S-Vap 5000 SA self-adhesive air and vapour control layer was installed onto the substrate followed by Sika Primer 600.

The Sikalastic 625 cold-applied liquid waterproofing membrane was then applied to these areas. Sika said that once again, use of the liquid system aided encapsulation of upstands and penetrations, and enabled easier detailing, particularly at the interfaces with the glazed canopy.

Jason Cross from Everlast (Rail) Limited said, “It was a challenging project requiring meticulous co-ordination but use of the versatile Sikalastic 625 liquid system enabled us to work with the unique design of the heritage building to deliver a robust and neat waterproofing solution.”