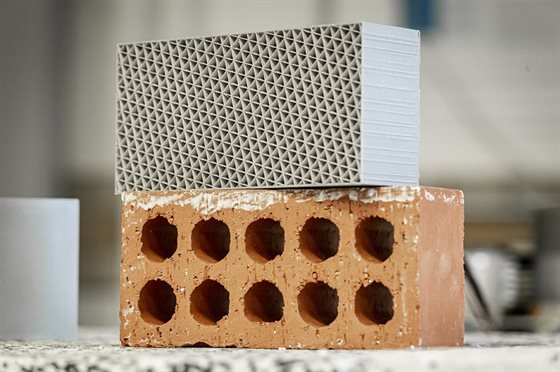

A university in Leicester has developed a brick made from domestic plastic waste that is claimed to provide ten times better insulation than traditional bricks made from clay.

Dr Karthikeyan Kandan, a senior lecturer in mechanical engineering at De Montfort University, came up with the design after studying the structure of the Baya weaver bird’s nest.

He said, “The Bayer Weaver bird’s nest’s ingenious construction gives it excellent thermal insulation and mechanical properties for inhabitation.

“Inside there is a central nesting chamber, which makes it the ideal micro-climate for inhabitation. By replicating this structure, we have manufactured a brick that improves energy efficiency of modern buildings and therefore can reduce carbon footprint.”

Created using 3D printing technology, the brick was tested by PHD student Saad Alqahtani. The student placed the brick in a hot-box calorimeter, and said that his tests showed that the brick has ten times better insulation than the traditional version.

Dr Kandan said, “Our brick, made from all kinds of domestic plastic waste – from coffee cup lids to plastic bottles – exhibits a tremendous thermal envelope over conventional building materials.

Saad added, “Our work has demonstrated that 3D printed bricks made from household plastic waste are thermally far superior than the existing bricks made in the market. This breakthrough can literally help us build the future.”

The creators say that they hope to get the brick into commercial production by the end of the year.