Every room presents a unique challenge when it comes to acoustics. When you place an incorrect material or even too much of one, it can spell disaster. From light to air movement, fire safety to access, the specification of any acoustic material must strike the right balance between functionality, effectiveness and aesthetics. Mike Carrick, head of acoustics at SIDERISE, looks into the art and science of acoustics

FROM the outset it’s important to use materials which will achieve good acoustics and solve any sound transmission issues whilst not compromising the aesthetics of the interior space. The designer must also not only satisfy the legislative requirements, but the client or end user’s ‘wish list’ of acoustic behaviour. Proper acoustics, the unobtrusive sum of all sounds, is the key objective for a comfortable environment.

Cross-talk

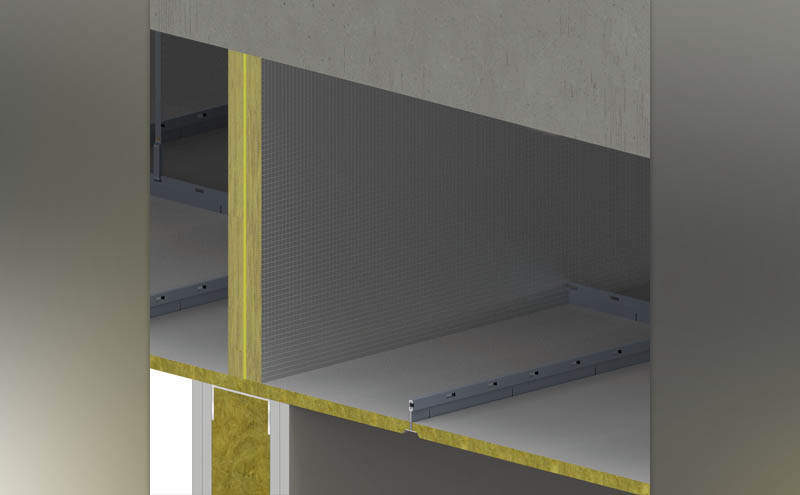

The sound separation achieved between adjoining rooms or offices is often severely limited by ‘cross-talk’ via a common void. This problem occurs when the transmission loss associated with this sound path is less than that provided by the primary separating element, for example, a partition. The voids affected by ‘cross-talk’ include suspended ceiling voids at partitions, access floor voids below partitions and cavities between the floor slab edges and external façades.

To effectively reduce sound transmission or ‘cross-talk’ via hidden voids which sit above office partitions, ceiling void barriers should be installed directly in-line with the partition.The Sound Reduction Index or SRI (Rw) of the cavity barrier is not normally required to equal that of the partition itself. The individual performance of the barrier need only be sufficient to correct the shortfall between the partition and the untreated cross-talk path.

Ceiling systems

The actual value of these paths can vary substantially. For ceiling voids, 15-40dB Dnf,w (DnCw) would usually be associated with most suspended ceiling systems. An acoustic engineer can assess a minimum SRI value for the cavity barrier with knowledge of either the existing overall path value or details of the individual path obstructing elements.

Occasionally, conditions arise that demand substantially higher SRI values of the cavity barrier, such as ceiling voids formed by open-cell or substantially perforated suspended ceilings. Twin barrier or multiple element arrangements can then be employed to accommodate almost all possible sound performance criteria. In this situation, Rw values are for the barrier arrangement alone. Room-to-room performance (DnCw) would normally be significantly higher.

Weakest link

The overall sound performance in a curtain wall building is effectively controlled by the ‘weakest link’. This means that very careful consideration should be given to any potential weak point to ensure it does not become the ‘limiting factor’ in the overall sound transmission performance. The curtain wall together with the movement joint should all be considered as potential weak points and thoroughly assessed accordingly.

Sound better

If you are looking to reduce vertical and horizontal sound transmission in curtain wall buildings, there are a number of effective and proven acoustic void barriers and barrier overlays for facades that deal with all common sound path problems. They are frequently used to assist in reducing flanking transmission between adjacent internal areas.

When considering the specification of the seal between the slab edge and the facade, it is all too often for product selection to be based exclusively in terms of compliance to the relevant fire regulations. For façade engineers, architects and their clients, it is essential that due consideration is given to both the acoustic implications and performance of the closure arrangement, ensuring any potential weak point in curtain walled buildings is controlled.

The cavity seal should ideally always be selected at the design stage because at this point, the largest range of suitable products is potentially available to the designer. Products can therefore be selected based on cost-effectiveness, ease of installation, and acoustic performance. Post or remedial treatment severely limits available product selection. Also, it is invariably more expensive, less practical to install and may not always be fully compliant.

While a superior acoustic environment should be a given, successful acoustic design is a detail-oriented process which requires good planning and the careful consideration of both specification and construction. The use of performance enhancing products will increase the internal amenity of a building, without impacting on design or cost.